-

Hot Melt

We provide release coatings on a number of parts that are exposed to hot-melt adhesives where “no-stick” and release is needed to improve productivity and clean-up.

Benefits:

No-stick and release is needed to improve productivity and clean-up.

Best Used For:

A wide range of converting processess.

View Details -

HVOF

In this process metal particles actually travel faster than the speed of sound, generating the best bond strengths, density and hardness of all our processes.

Benefits:

HVOF does not reach temperatures that are attainable with plasma processes so materials such as ceramicsare not processed with this technique.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Hydro Cracker Reactors

Hydro cracker reactors vessels commonly have issues with corrosion and fouling.

Benefits:

Engineer and apply coatings that can address corrosion and fouling.

Best Used For:

A wide range of industries and applications

View Details -

Laser Cladding

Laser cladding is an additive manufacturing process that utilizes a laser to metallurgically bond performance coatings to a product’s base material.

Benefits:

The process uses the laser to create a melt pool of the base material. The coating material is introduced into this melt pool in either powder or wire form.

Best Used For:

A wide range of cladding applications; including small footprint applications.

View Details -

Liquid Dispersion

Liquid dispersion is a polymer coating process technique used in a wide variety of applications.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

Low Friction

Reduce the cleanup and buildup of such materials as starches, paints, adhesives, latex, rubber, food, paper, ice, sugar, resins, tapes, inks.

Benefits:

Extremely wear resistant and long lasting.

Best Used For:

Hard base onto your part and then impregnate one of our Low COF release agents into that coating.

View Details -

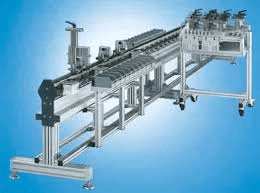

Machine Frame

We deisgn, engineer and apply coatings to machine frames for wear and corrosion resistance to extend their life spans.

Benefits:

Service is provided on-site.

Best Used For:

A wide range of industries and applications

View Details -

Mixing Equipment

Mixing equipment is used to blend a wide range of materials.

Benefits:

Apply wear-resistant and non-stick coatings to the mixer surfaces to enhance performance.

Best Used For:

A wide range of industries and applications

View Details -

Mixing Vessels/Paddles

Mixing vessels/paddles are used to blend a wide range of materials.

Benefits:

Apply wear-resistant and non-stick coatings to the mixer surfaces to enhance performance.

Best Used For:

A wide range of industries and applications

View Details -

Molds

We manufacture durable, wear-resistant, release coatings for molds, and various other molding equipment, to resist and protect against product build-up.

Benefits:

Resist and protect against product build-up.

Best Used For:

A wide range of industries and applications

View Details -

Nickel Plating

Electroless Nickel plating offers some advantages over chrome plating. It has a better resistance to corrosion with relatively thinner coatings than chrome.

Benefits:

Electroless Nickel plating in the as-plated condition has a hardness of approximately 50Rc. It can be heat treated by baking to a hardness of approximately 70Rc.

Best Used For:

Electroless Nickel plating can be applied to aluminum and steel.

View Details -

Non & Conductive Coatings

Conductive and non-conductive coatings are used promote or limit the flow of heat or electrical current into or away from the object that is coated.

Benefits:

Wide variety of metal, metal alloy, carbide matrix, ceramic, and polymer coatings available with these properties as well as combination coatings composed of thermal spray and polymer coatings.

Best Used For:

Conductive and non-conductive surface properties.

View Details -

Ovens

We engineer and apply high release coatings for ovens. Our coatings help oven components resist product build-up, which reduces the need for maintenance.

Benefits:

Resist product build-up, which reduces the need for maintenance.

Best Used For:

A wide range of industries and applications

View Details -

Paddle Blade Mixer

Paddle Blade Mixers are used to blend a wide range of materials.

Benefits:

Apply wear-resistant and non-stick coatings to the mixer surfaces to enhance performance.

Best Used For:

A wide range of industries and applications

View Details -

Plasma Spray

In this process we use various gasses that are ignited by an electric arc. Temperatures can rise up to 30,000° F while the part temperature remains at less than 200°F.

Benefits:

Particle velocity is greater than in the other four systems. One of the benefits of using this system is the high heat, which can process materials with high melting points (including ceramics).

Best Used For:

Utilized to apply metal and ceramic based coatings.

View Details -

Plasma Transferred Arc

We manufacture and utlize plasma transferred arc welding or cladding systems to provide wear and corrosion resistant coatings or claddings.

Benefits:

Provide a protective wear layer or rebuild parts back to original dimensional integrity.

Best Used For:

This technology is used to rebuild surfaces back to original dimensional integrity.

View Details -

Plating

Plating often involves two process materials and/or steps where the first material bonds to the base material and serves as the primer for finish plating.

Benefits:

A wide range of surface property enhancements.

Best Used For:

A wide variety of applications.

View Details -

Powder Coat

The powder coat process is used in many of our polmyer coating processes.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

Pump Components

Pump components are subjected to wear, corrosion, and cavitation damage. We supply turnkey components and coating services to help address these problems.

Benefits:

Longer service life.

Best Used For:

Pump components.

View Details -

Reactors

Reactors are devices that contain and control nuclear, chemical, or fusion reactions.

Benefits:

Offer corrosion resistant coatings able to withstand these conditions.

Best Used For:

Used within the power and chemical industry.

View Details -

Release & Cleanability

Certified DuPont Licensed Industrial Applicator (DLA), user of Whitford coatings, and we blend our own, resulting in leading the industry in release coating services for a variety of industries.

Benefits:

Non-stick and release properties on surfaces.

Best Used For:

Our coatings reduce the clean up and build-up of such materials as starches, paints, adhesives, latex, rubber, food, paper, ice, sugar, resins, tapes, inks.

View Details -

Screens

Screens and screening systems are often subjected to wear, corrosion, and build-up.

Benefits:

Extend service life and prevent product build up.

Best Used For:

A wide range of industries and applications

View Details -

Screw Conveyor

We apply non-stick and low-friction coatings to the inside of screw conveyors to improve flow, downtime, and yield for the powder, bulk, and food industries.

Benefits:

Extend service life and prevent product build up.

Best Used For:

Powder, bulk, and food industries.

View Details -

Scrubber Columns

Scrubber columns are used to remove pollutants, heat, and particulates from processing.

Benefits:

Specialized coatings to help combat their corrosion and wear.

Best Used For:

Used in the chemical and petrochemical industry.

View Details -

Side Face and Journals

Side faces and journals on rollers need increased protection,reburbishment and repair.

Benefits:

Extend service life.

Best Used For:

A wide range of industries and applications

View Details -

Solvent Extraction Units

Solvent extraction units are applied with corrosion-resistant and non-stick coatings for protection within the variety of industries they are utilized.

Benefits:

Corrosion-resistant and non-stick coatings for protection.

Best Used For:

A wide range of industries and applications

View Details -

Splash Guards

Splash guards are mounted to machinery to prevent chemicals from reaching the operator.

Benefits:

For chemical coated splash guards, our coatings make cleanup easier.

Best Used For:

A wide range of industries and applications

View Details -

Steam Hoods

Steam hoods are used where hot water steam is collected.

Benefits:

Offer FDA compliant non-permeable Plasma Coatings that withstand high temperatures to prevent corrosion.

Best Used For:

A wide range of industries and applications

View Details -

Storage Equipment/Tanks

Storage equipment, like tanks, are used to store manufacturing material.

Benefits:

Offer a variety of durable non-stick and wear-resistant coatings for tank interiors.

Best Used For:

A wide range of industries and applications

View Details -

Sulfur Condenser Head

Sulfur condensers require corrosion-resistant linings because of the environment they are used in to reclaim sulfur from hydrogen sulfide in raw natural gas.

Benefits:

Extend service life.

Best Used For:

A wide range of industries and applications

View Details

Showing 31–60 of 77 results