American Roller Solutions for the Flexible Packaging Industry

Maximize productivity through advanced traction, grip, and release properties only found with American Roller’s Covering and Plasma Coating Technology for the Flexible Packaging Industry!

American Roller offers custom coating and soft covering technology that maximizes efficiency and performance with each roller position for years to come.

Custom in-house formulations are available to accommodate your specific film grade and process.

Roller Performance

ELIMINATE

- Wrap-ups, even under max speed

- Web-breaks that create downtime

- Defects created by knife cuts

- Drag, slippage, and wrinkles

MAXIMIZE

- Durability

- Anti-static capabilities

- Release properties

- Splice transfers

- Thermal transfer properties

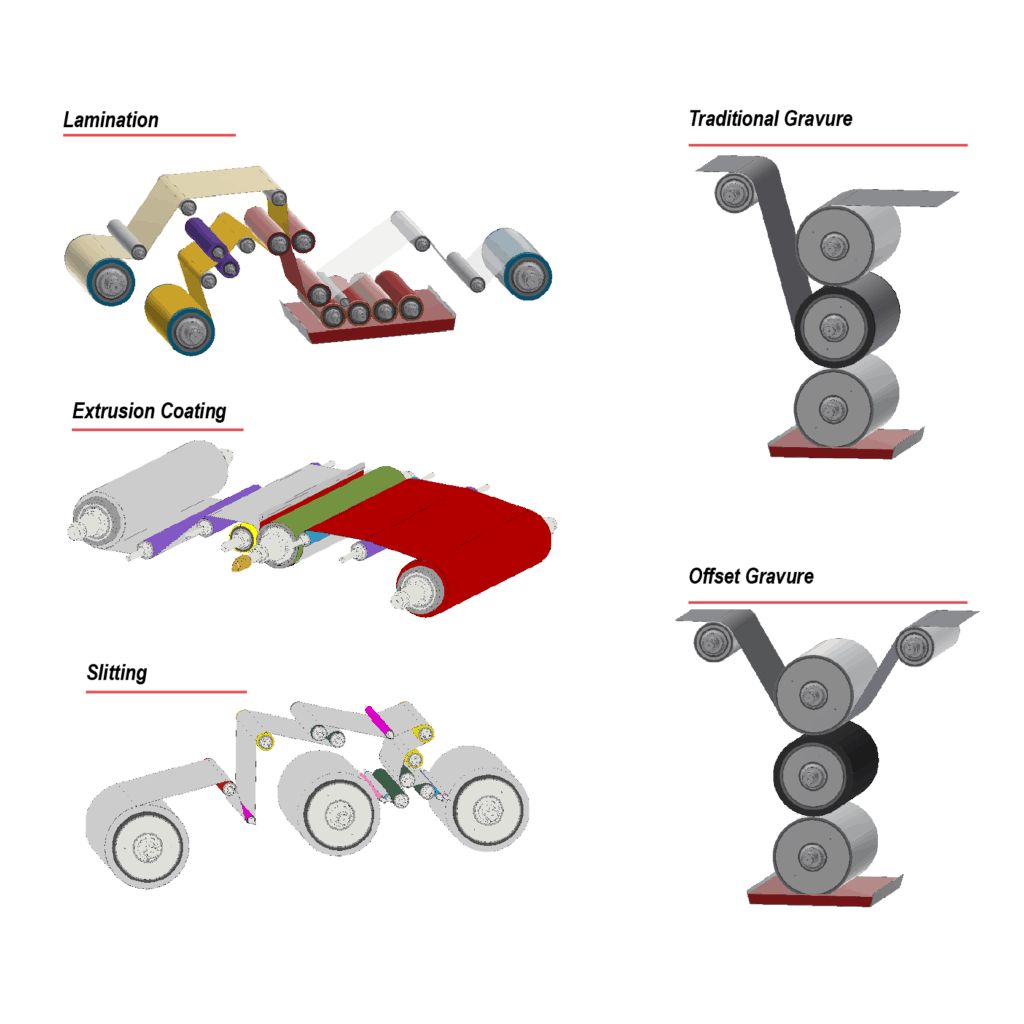

Roller Positions

PLASMA COATINGS

- Entrance/Exit Winder Rollers

- Coating Pan

- Backing Roller

- Transfer Idlers

- Chill Roller

- Adhesive Pan

- Load Cell Rollers

- Oven Idlers

- Drive Rollers

- Bed Rollers

- Transfer Idlers

- Tension Leveler Rollers

- Lay On Rollers

- And more…

SOFT COVERINGS

- Coating Rolls

- Laminating Rolls

- General Nip Rolls

- Lay On Rolls

- Wrinkle Elimination Rolls

- Bowed Rolls

- S-Wrap Rolls

- Extrusion Nip Rolls

- Bed Rolls

- And more…

Recommended Products for the Flexible Packaging Industry

PC-900 Series

OEMs have relied on our original traction release coating system for decades. A versatile coating that can be used on any roll position where exceptional traction and good release characteristics are required. Often used in roll positions that see high angles of wrap.

PC-11000 Series

This next-generation, dual-layer, traction release coating system was engineered with maximum durability in mind. Features high COF for added traction and excellent release properties for use in the most demanding roll positions.

PC-12000 Series

Offers maximum release of adhesives and debris buildup. Provides high-traction, excellent web-tracking, and great wear resistance.

PC-315

One of our smoothest release coatings providing excellent release and low friction. Ideal for use on oven idlers that are exposed to constant temperatures up to 500F (can be exposed to 550F for intermittent use). Excellent option for reduced cleaning of coating pans and drool tubs.

HR Excelnip 27000

A specially formulated soft covering designed for extreme wear, abrasion resistance, also possessing exceptionally high release properties never before seen in the industry.

Arcomax 6000 (anti-static)

Next-generation EPDM that has been re-engineered from the compound up. Significant improvements have been achieved with abrasion resistance and the overall compression set, including a new never before used non-marking colorant.

Pegasus

A proprietary formula for bump/splice rollers with a high release coating option that offers excellent resistance to adhesive buildup for more efficient web splicing. A foam covering offers superior compression and tear resistance.