-

Acid Flushing

Acid flushing breaks down and flushes out the internal corrosion deposits and blockages in heat transfer rollers to improve flowrates and improve thermal conductivity.

Benefits:

Improves efficiencies in heat transfer rates.

Best Used For:

Heat Transfer and Chill Rolls

View Details -

Analytical Property Testing

Specific testing methods that include; Ash and Soxhlet Extraction Analysis, FT-IR Analysis by Diamond ATR, and FT-IR Spectrophotometric Analysis.

Benefits:

Identify root cause problems and limitiations from current performance.

Best Used For:

This is used to understand material composition and improve upon performance characteristics.

View Details -

Ash and Soxhlet Extraction Analysis

Ash and soxhlet extraction analysis is one of the services we offer as part of our analytical property tests.

Benefits:

Identify root cause problems and limitiations from current performance.

Best Used For:

It is the process of transferring partially soluble components of a solid to the liquid phase using a Soxhlet extractor for material and composition analysis.

View Details -

Balancing

Two plane and 3 plane balancing is a common request. Detailed balance reports are provided post-balancing, ensuring that roller and parts perform in an optimal manner.

Benefits:

This is increasingly important in today's high running machine speeds.

Best Used For:

Roll and machine balance.

View Details -

Box Repair

We offer roller and crating repairs on storage and transport boxes, which are repaired and refurbished with our in-house capabilities.

Benefits:

Re-store transportation containers reducing cost.

Best Used For:

Box Repair

View Details -

Building-Up & Re-machining Journals

Building up (welding) and re-machining is usually done if a journal is worn, damaged, or simply bent- ultimately impacting the performance of web processing.

Benefits:

Re-store journals to original and critical dimensions; thus reducing replacement costs.

Best Used For:

Journal Repair

View Details -

Centerless Grinding

Centerless grinding is process that uses abrasive cutting to remove material. This differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece.

Benefits:

Workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece.

Best Used For:

A wide variety of applications.

View Details -

Chemical Resistance Property Testing

These tests are conducted to determine chemical resistance characteristics of a covering, coating or finished part.

Benefits:

(1) Customer Media Immersion Testing (2) Volume, Weight and Hardness Change Data (3) Corrosion Resistance Testing (4) Solvent Wipe Testing

Best Used For:

Wide range of problem solving applications around corrosion protection.

View Details -

Chevron or Herringbone Grooving

Spreader rollers grooving can take many forms including: herringbone pattern, chevron groove pattern, reverse taper configuration, and grooved rubber covers.

Benefits:

Improved web handling; wrinkle release

Best Used For:

Bowed roll and stretch roll applications.

View Details -

Coating Thickness and Condition

Through our on-site and in-house capabilities we assess coating thickness and condition, which is an important measurement when understanding resurfacing or reconditioning needs.

Benefits:

Identify current life of coating layer.

Best Used For:

Wide range of applications.

View Details -

Compression Load Deflection Testing

Compression Load Deflection Testing is one of the services we offer as part of our physical property tests.

Benefits:

This is useful in determing how a rubber covering will perform in a process condition.

Best Used For:

It is a nondestructive method for determining relationship between compressive load and deflection under load for vulcanized rubber. (ASTM D-575).

View Details -

Core Repair

Rebuilding cores is a routine service we perform. We also possess the capability to provide metrics on frequency of core repair so as to manage spends in the most cost effective way.

Benefits:

We can provide FEA analysis to help solve issues with production.

Best Used For:

Core Repair

View Details -

Corrosion Resistance Testing

Corrosion Resistance Testing is one of the services we offer as part of our Chemical Resistance Property Testing.

Benefits:

Often this is an important test in determining the correct material and application process for coating or covering your parts in the application targeted.

Best Used For:

Wide range of applications.

View Details -

Dimension Checks for Journal and Body

Dimension checks for journal and bodies are reviews of a roller journal and body used to verify dimensions and advise on repairs or reconditioning as needed.

Benefits:

Re-store rollers to original state.

Best Used For:

Journal and Core Body Repair

View Details -

Durometer Measure

Durometer is the international standard used for measurement of rubber hardness in the roller industry and also refers to the instrument itself.

Benefits:

Measure and control roller hardness.

Best Used For:

This is a standard specification we define some products and servics with, providing documentation to our customers.

View Details -

Dynamic Abrasion Testing

Dynamic abrasion testing is one of the services we offer as part of our dynamic property testing.

Benefits:

This test is used in the pursuit of designing longer-lasting coverings and coatings.

Best Used For:

This test is used to determine resistance to wear of a particular coating or covering.

View Details -

Dynamic Property Testing

These tests are utilized to understand a coating or coverings response to pressure, heat and wear.

Benefits:

The tests include: Static Release Dynamic Abrasion Testing Pilot Testing Hysteresis (Heat Buildup) Testing

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

FT-IR Spectrophotometric Analysis

FT-IR spectrophotometric analysis is one of the services we offer as part of our analytical property testing.

Benefits:

This is used to understand material composition and peformance characteristics so that the optimal material and finish recommendation can be provided for a given application.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Hardness Testing

Harness testing is one of the services we offer as part of our physical property testing.

Benefits:

This type of testing helps us better understand current state and correlate the data to recommendations on better performing materials for the application.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

ID Grinding

We perform Internal Diameter Grinding on complex parts.

Benefits:

Smooth internal diameter surface finish.

Best Used For:

A wide variety of applications.

View Details -

Knurled and Ground finishes

Available in a variety of aluminum and steel, our knurled and ground finishes are available for the manufacturing and repair of custom converting rollers.

Benefits:

Custom finish solutions.

Best Used For:

A wide variety of applications.

View Details -

Machined Crowns

Roller crowning is intended to ensure proper web alignment and helps minimize the effects of deflection. Materials include several types of aluminum and steel.

Benefits:

Minimize the effects of deflection.

Best Used For:

A wide variety of applications.

View Details -

Mag. Particle Test

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) test for detecting surface and subsurface discontinuities in materials such as iron, nickel, cobalt, and some of their alloys.

Benefits:

Ensures product quality and uniformity.

Best Used For:

Often used as a quality verification process.

View Details -

Magna Flux Test

A magna flux test is a non-destructive testing (NDT) process for detecting surface, and subsurface, discontinuities in materials such as: iron, nickel, cobalt, and some of their alloys.

Benefits:

This process puts a magnetic field into the piece and the piece can be magnetized by direct or indirect magnetization.

Best Used For:

Often used as a quality verification process.

View Details -

Media Immersion Testing

Application media immersion testing is one of the services we offer as part of our Chemical Resistance Property Testing.

Benefits:

Chemical Resistance Property Testing.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Mirror Finishing

Chrome plating is used where a “mirror” finish is needed.

Benefits:

Mirror finishing is a very smooth surface and can either decrease or increase web/roller friction.

Best Used For:

A wide variety of applications.

View Details -

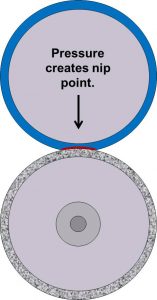

Nip Impressions

A nip impression is a measure of the uniformity of the pressure in a web processing nip. The pressure profile is sometimes referred to as a footprint.

Benefits:

This is useful in understanding how a machine is running or can run better. The company can provide a service in measuring the nip impression.

Best Used For:

Wide range of problem solving applications and analysis in the nip roll position of a web processing machine.

View Details -

Non Destructive Testing

Non destructive testing is analysis techniques used to evaluate the material of a roller or part without damaging it.

Benefits:

There is a wide variety of non-destructive tests utilized.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Overlaying Weld

Overlaying welds are utilized to help build up a roller’s body to a larger diameter, repair existing faces on rollers, or incorporate different properties.

Benefits:

Re-store to original and critical dimensions; thus reducing replacement costs.

Best Used For:

Core and Journal Repair

View Details -

Ozone Resistance Testing

Ozone resistance testing is one of the services we offer as part of our physical property testing.

Benefits:

Ozone resistance testing

Best Used For:

Wide range of problem solving applications and analysis.

View Details

Showing 1–30 of 50 results