-

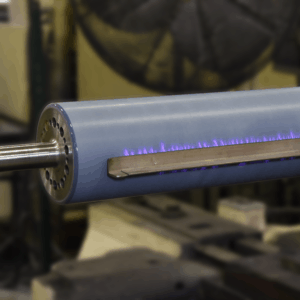

ARCOTRON

The industry leader and standard for a complete product line of corona treater coverings.

Benefits:

Arcotron specialty rollers comes in eight (8) specific solutions for use in elastomer, epoxy, and ceramic treater applications. With 100% corona treater testing prior to shipment, you are ensured the highest quality and longest lasting treater roll with the strongest warranty on the market.

Best Used For:

Corona Treater applications

View Details -

Charge Rollers

Charge rollers are used to transfer or project electrostatic charges.

Benefits:

Coated with thermal spray ceramics and other elastomeric material.

Best Used For:

Charge rollers are used to transfer or project electrostatic charges.

View Details -

Chrome Plating

Standard Chrome plating for new cores as well as re-chroming of used cores.

Benefits:

Corrosion protection and other key surface protection properties

Best Used For:

Heat transfer and chill rolls; other surfaces requiring corrosion protection.

View Details -

Chrome Plus +

Chrome Plus is a environmentally friendly carbide coating replacement for Chrome. With equivalent price, performance, surface finish and thermal transfer properties.

Benefits:

Green replacement for Chrome. A scratch resistant and repair capable coating for use in a wide variety of applications.

Best Used For:

Heat transfer and chill rolls and other metals surfaces.

View Details -

LIMISTAT

Limistat is a series of electrically conductive rubber covered rollers designed to aid in dissipating static produced by webs.

Benefits:

Reduce static build-up in high speed web applications.

Best Used For:

Limistat functions best in high-speed webs that suffer from static electricity buildup.

View Details -

Pellex

Pellex offers specially formulated proprietary coverings and coatings that offer excellent abrasion resistance and overall force resistance which allows accurate delivery of the strands to the cutting unit, producing consistent, uniform pellets.

Benefits:

Specially formulated covering has outstanding abrasion resistance which allows for accurate delivery of the strands to the cutting unit, producing consistent, uniform pellets.

Best Used For:

Pelletizing equipment

View Details -

PLASMA 11000 SERIES

Coatings from our PLASMA 11000 series offer excellent release of adhesives and rubber.

Benefits:

This series provides high traction, excellent web tracking and wear resistance.

Best Used For:

Roll positions requiring and traction release associated with adhesives or other sticky materials.

View Details -

PLASMA 12000 SERIES

Coatings from our PLASMA 12000 series feature excellent release of adhesives with superior toughness and solvent resistance.

Benefits:

They are also applicable on-site at your facility.

Best Used For:

Roll positions requiring and traction release associated with adhesives or other sticky materials.

View Details -

PLASMA 15000 SERIES

Coatings from our PLASMA 15000 series offer a tough, low friction, dry lubricant with moderate release.

Benefits:

While maximum process temperature is documented at 700°F (LT series is 400°F), lower temperatures can be utilized if needed.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 17000 SERIES

Coatings from our PLASMA 17000 series are tough, low friction, dry lubricant coatings with good release.

Benefits:

Tough, low friction, dry lubricant coatings with good release.

Best Used For:

Ideal for conveying and sliding applications.

View Details -

PLASMA 18000 SERIES

Coatings from our PLASMA 18000 series are tough, high temperature release coatings with low friction.

Benefits:

Very versatile coatings that provide high release across a wide variety of applications. In addition, they provide one of the highest service temperatures of all coating series.

Best Used For:

A wide variety of high temperature applications.

View Details -

PLASMA 200 HT SERIES

Coatings from our PLASMA 200 HT series are release coatings designed for high temperature applications.

Benefits:

They have a max service temperature of 500°F.

Best Used For:

A wide variety of high temperature applications.

View Details -

PLASMA 200 SERIES

Coatings from our PLASMA 200 series are our toughest and original release coatings.

Benefits:

They provide excellent release, low friction, and abuse resistance.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 20000 SERIES

Coatings from our PLASMA 20000 series offer excellent corrosion resistance, release, and cleanability.

Benefits:

Combination of the material type and thickness results in excellent resistance to permeation.

Best Used For:

A wide variety of high temperature applications.

View Details -

PLASMA 21000 SERIES

Coatings from our PLASMA 21000 series are smooth release coatings that offer excellent corrosion resistance, low friction, and release of most materials including adhesives.

Benefits:

They are applicable on-site at your facility.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 25000 SERIES

Coatings from our PLASMA 25000 series have an ambient cure coating which offers outstanding traction, web tracking, release, and toughness.

Benefits:

This series is our smoothest version of a traction/release coatings. This is the bake, cured version of the 10000 series.

Best Used For:

This is an ideal replacement for any traction alternative currently being used, such as tapes, cheese grate, sandpaper, and certain rubber coverings.

View Details -

PLASMA 27000 SERIES

Coatings from our PLASMA 27000 series are smooth, ambient cure, release coatings that offer excellent corrosion resistance, low friction, and release of most materials including adhesives.

Benefits:

They are FDA compliant for indirect food contact only and are applicable on-site at your facility.

Best Used For:

A wide variety of FDA compliant applications.

View Details -

PLASMA 28000 SERIES

Coatings from our PLASMA 28000 series are smooth, tough, release coatings that offer excellent release, low friction, corrosion resistance, and bond strength.

Benefits:

They are applicable on-site at your facility.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 300 SERIES

Coatings from our PLASMA 300 series are one of our smoothest release coatings, providing excellent release and low friction.

Benefits:

Smoothest release coatings, providing excellent release and low friction.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 30000 SERIES

Coatings from our PLASMA 30000 series have a cross-linked polymer which yields a wide range of chemical resistance.

Benefits:

This coating is formulated to meet specific service requirements while retaining temperature, chemical, and other physical properties.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 31000 SERIES

Coatings from our PLASMA 31000 series are sealed coatings that provide excellent corrosion resistance.

Benefits:

Excellent corrosion resistance.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 32000 SERIES

Coatings from our PLASMA 32000 series are superior polymer coatings that provide toughness, abuse-resistance, and low friction.

Benefits:

Provide toughness, abuse-resistance, and low friction.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 33000 SERIES

Coatings from our PLASMA 33000 series provide chemical resistance.

Benefits:

Thickness ranges from .010 to .100, dependent on application and material. They are applicable on-site at your facility.

Best Used For:

A wide variety of applications requiring good chemical resistance.

View Details -

PLASMA 34000 SERIES

Coatings from our PLASMA 34000 series utilize multiple layers of resins to build up the protection that metal and concrete need in chemical manufacturing or processing operations.

Benefits:

When fully cured, the separate elements lose their individual identity and become a single, monolithic coating; providing superior chemical resistance. They are applicable on-site at your facility.

Best Used For:

A wide variety of applications requiriing good chemical resistance and the ability to be applied on-site.

View Details -

PLASMA 36000 SERIES

Coatings from our PLASMA 36000 series use multiple resins to build up the protection that metal and concrete need in chemical, manufacturing or processing operations.

Benefits:

When fully cured, the separate elements lose their individual identity and become a single, monolithic coating; providing superior chemical resistance. They are applicable on-site at your facility.

Best Used For:

A wide variety of applications requiriing good chemical resistance and the ability to be applied on-site.

View Details -

PLASMA 400 SERIES

Coatings from our PLASMA 400 series are designed for high traction and wear resistance with a particle hardness up to 72 Rc.

Benefits:

High traction and wear resistance. They are applicable on-site at your facility.

Best Used For:

A wide variety of applications requiring traction and wear resistance.

View Details -

PLASMA 40000 SERIES

Coatings from our PLASMA 40000 series are tough, high temperature, release coatings with low friction. These PTFE/PFOA free, FDA compliant, non-stick coatings can survive temperatures up to 1,000°F!

Benefits:

High temperature, release coatings with low friction. These FDA compliant, non-stick coatings can survive temperatures up to 1,000°F!

Best Used For:

They work best for applications in which coating hardness, extreme temperature resistance, and slip are the main requirements.

View Details -

PLASMA 42000 SERIES

Coatings from our PLASMA 42000 series are specialty release coatings that provide excellent release, low friction, and abuse resistance.

Benefits:

Provide excellent release, low friction, and abuse resistance. These coatings offer superior release of high sugar content products.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 43000 SERIES

Coatings from our PLASMA 43000 series are a specialty polymer and offer a smooth coating with enhanced release characteristics and superior resistance to permeation.

Benefits:

Smooth coating with enhanced release characteristics and superior resistance to permeation.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 45000 SERIES

Coatings from our PLASMA 45000 series represent our line of Electroless Nickel offerings.

Benefits:

Electroless Nickel coatings provide wear resistance, low COF, and corrosion protection. With PTFE to some of the electroless nickel systems: lower cof, higher release, and increased hardness can be obtained.

Best Used For:

A wide variety of applications.

View Details

Showing 1–30 of 36 results