-

Accumulator Rollers

Accumulator roller are used in film and metal handling lines.

Benefits:

Ozone and abrasion resistant, and do not degrade from oils or corrosive materials.

Best Used For:

Accumulator Rollers

View Details -

Anilox Rollers

Anilox rollers are engraved or coated with a porous surface to contain ink, adhesive, or liquid until its application.

Benefits:

Uniform printing.

Best Used For:

Printing ink distribution

View Details -

Anti-static Idler Rollers

Anti-static idler rollers are manufactured and used to reduce static electricity build-up.

Benefits:

Reduce statis electricity on high speed web processing machines.

Best Used For:

They are used within the paper, film, foil, and plastic industries.

View Details -

Anvil Rollers

Anvil rollers, also known as slitter rollers, are hardened rollers on which a circular cutter rides in order to part, slit or perforate the web.

Benefits:

Some slitter rollers are multi-grooved over which a razor or razors are mounted to slit the web.

Best Used For:

Anvil rollers are used for slitting (separating) applications.

View Details -

Back Up Rollers

Back up rollers are used in various applications to provide stability and thermal enhancements.

Benefits:

We offer various covers for our rollers for optimal coverage.

Best Used For:

Back Up Rollers

View Details -

Breast Rollers

Breast rollers are used within the paper industry in the first phase of forming a sheet of paper.

Benefits:

Coated breast rollers for corrosion and wear-resistance.

Best Used For:

Breast Rollers

View Details -

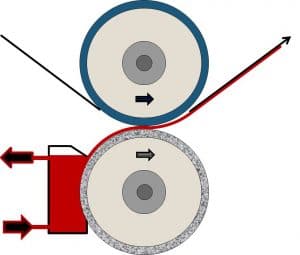

Bump Rollers

Bump rollers are manufactured and used for splicing and/or joining two webs together.

Benefits:

Used within the paper, film, foil, and plastic industries.

Best Used For:

Bump Rollers

View Details -

Ceramic Heater Technology Rollers

Our ceramic heater rollers are coated to provide uniform temperature at their surface, providing unmatched temperature uniformity and efficient heat transfer.

Benefits:

Temperature uniformity and efficient heat transfer.

Best Used For:

Heat transfer rolls.

View Details -

Charge Rollers

Charge rollers are used to transfer or project electrostatic charges.

Benefits:

Coated with thermal spray ceramics and other elastomeric material.

Best Used For:

Charge rollers are used to transfer or project electrostatic charges.

View Details -

Coating Rollers

We design and manufacture coating rollers, which are involved in the application process of coating substrates such as: paper, fabric, film, foil, and more.

Benefits:

Apply even coat weight due to uniformity.

Best Used For:

Coating Rollers

View Details -

Couch Rollers

Couch rollers are used within the paper industry in the first phase of forming a sheet of paper.

Benefits:

Cover couch rollers for corrosion and wear-resistance.

Best Used For:

Couch Rollers

View Details -

Deflector Rollers

Deflector rollers are used to turn webs and substrates.

Benefits:

Ozone and abrasion resistant, and will not degrade from oils or corrosive materials.

Best Used For:

Deflector Rollers

View Details -

Delivery Rollers

Delivery rollers aid in the delivery of substrates across web paths.

Benefits:

ffer various elastomeric compound roller coverings specific to application.

Best Used For:

Delivery Rollers

View Details -

Draw Rollers

Draw rollers are driven nip rollers that pull substrates.

Benefits:

Rollers are ozone and abrasion resistant, and will not degrade from oils or corrosive materials.

Best Used For:

Draw Rollers

View Details -

Dryer Drums

We coat dryer drums with durable, speciality formulated non-stick surfaces.

Benefits:

Allows dryer drums to run at higher speeds, with less sheet breaks and contamination or build up issues.

Best Used For:

Dryer Drums

View Details -

Embossing Back Up Rollers

Embossing back up rollers are used to create a nip under pressure, which creates a pattern on substrates.

Benefits:

Elastomeric roller coverings maximize performance.

Best Used For:

Embossing Back Up Rollers

View Details -

Embossing Rollers

Embossing rollers are used to create patterns on substrates.

Benefits:

Multiple surface finish roller bases for high performance and long term wear resistance.

Best Used For:

Embossing Rollers

View Details -

Expander Rollers

Expander rollers are used to expand the web by eliminating wrinkles. We offer various web spreading rollers including: bowed, crowned, concaved, and more.

Benefits:

Used to expand the web by eliminating wrinkles.

Best Used For:

Bowed roll and stretch roll applications.

View Details -

Felt Rollers

Felt rollers are used to support and guide felt, but often experience contamination.

Benefits:

Our wear-resistant and release coatings protect felt rollers from contamination and increase run-time.

Best Used For:

Felt Rollers

View Details -

Flame Treating Back Up Rollers

Flame treating back up rollers are manufactured with corrosion and heat-resistant coatings as protection from the high temperatures during flame treating.

Benefits:

Longer service life in high temperatures.

Best Used For:

Flame Treating Back Up Rollers

View Details -

Foam Rollers

Foam rollers are manufactured from cellular material and used in a wide variety of applications and industries.

Benefits:

The "soft" core is supported by "tough" shell for improved wear resistance.

Best Used For:

Bump and splicing roll positions.

View Details -

Glue Rollers

Coating glue applicator rollers allows for easier cleanability during normal maintenance.

Benefits:

We have various coatings to match a solution to your glue or adhesive. Plasma Coatings 11,000 Series is a good choice.

Best Used For:

Glue Rollers

View Details -

Guide Rollers

Guide rollers guide substrates through the web’s path.

Benefits:

Custom formulations.

Best Used For:

Guide Rollers

View Details -

Hold Down Rollers

Hold down rollers are used to hold down webs and coils.

Benefits:

Rollers are ozone and abrasion resistant, and will not degrade from oils or corrosive materials.

Best Used For:

Hold Down Rollers

View Details -

Infeed Rollers

Indeed rollers are used to deliver products down the line to the next operation. We have multiple roller coverings including elastomeric and ceramic coverings.

Benefits:

Maximize printing performance.

Best Used For:

Infeed Rollers

View Details -

Laminating Rollers

Our laminating rollers are available in alloy steel, carbon steel, and stainless steel.

Benefits:

part of manufacturing processes to permanently assemble objects

Best Used For:

used within the paper, film, foil, and wood industries.

View Details -

Layon Rollers

Layton rollers are manufactured and used to help reduce air entrapment when winding.

Benefits:

Higher speeds on web processing machines with tighter parent roll properaties.

Best Used For:

They are utilized within the paper, film, foil, and plastic industries.

View Details -

-

Metering Rollers

Metering rollers are nipped to coating rollers to transfer thickness of coatings to substrates.

Benefits:

Application of proper coat weights.

Best Used For:

Metering Rollers

View Details -

Nip Rollers

Our nip rollers are available in alloy steel, carbon steel, and stainless steel. Nip rollers are also known as pinch rollers and by various other names.

Benefits:

Proper selection affects product quality and line speeds.

Best Used For:

They are used to press two or more sheets together to form a laminated product.

View Details

Showing 1–30 of 58 results