-

Anilox Rollers

Anilox rollers are engraved or coated with a porous surface to contain ink, adhesive, or liquid until its application.

Benefits:

Uniform printing.

Best Used For:

Printing ink distribution

View Details -

Anti-static Idler Rollers

Anti-static idler rollers are manufactured and used to reduce static electricity build-up.

Benefits:

Reduce statis electricity on high speed web processing machines.

Best Used For:

They are used within the paper, film, foil, and plastic industries.

View Details -

Anvil Rollers

Anvil rollers, also known as slitter rollers, are hardened rollers on which a circular cutter rides in order to part, slit or perforate the web.

Benefits:

Some slitter rollers are multi-grooved over which a razor or razors are mounted to slit the web.

Best Used For:

Anvil rollers are used for slitting (separating) applications.

View Details -

ARCOSTRETCHER

Arcostretcher rollers are available in single, double, quad or six groove patterns.

Benefits:

Ideal for handling very thin substrates and allows converters to run these thinner substrates at lower tensions and higher line speeds for better productivity.

Best Used For:

Bowed roll and stretch roll applications.

View Details -

ARCOTRON

The industry leader and standard for a complete product line of corona treater coverings.

Benefits:

Arcotron specialty rollers comes in eight (8) specific solutions for use in elastomer, epoxy, and ceramic treater applications. With 100% corona treater testing prior to shipment, you are ensured the highest quality and longest lasting treater roll with the strongest warranty on the market.

Best Used For:

Corona Treater applications

View Details -

Back Up Rollers

Back up rollers are used in various applications to provide stability and thermal enhancements.

Benefits:

We offer various covers for our rollers for optimal coverage.

Best Used For:

Back Up Rollers

View Details -

Bowed Rollers

Bowed rollers address web handling and wrinkling problems in a wide variety of materials and web speeds.

Benefits:

Can be rubber covered or steel segmented and can have a fixed or adjustable bow.

Best Used For:

Bowed roll and stretch roll applications.

View Details -

Bump Rollers

Bump rollers are manufactured and used for splicing and/or joining two webs together.

Benefits:

Used within the paper, film, foil, and plastic industries.

Best Used For:

Bump Rollers

View Details -

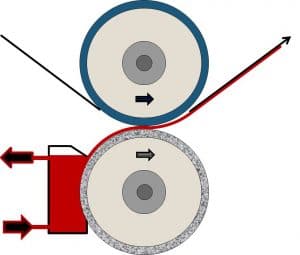

Calender Rollers

Calender rollers, which are usually configured in pairs, are used to gauge a web to a predetermined thickness by running the web through a controlled gap.

Benefits:

Calender rollers are series of hard pressure rollers that are used on-line or off-line to form or smooth a sheet of material like paper or plastic film.

Best Used For:

Calendar Rollers

View Details -

Carbon Fiber Rollers

Rollers that are primarily used when both high strength and low weight are needed. We also manufacture and coat carbon fiber unwind and rewind shafts and reel spools.

Benefits:

Referred to as our Valcom product; unique in the industry with bonding techniques that enable us to be only supplier to provide hard facing and ceramic coatings to a ground finish on carbon fiber rolls!

Best Used For:

Carbon fiber rolls.

View Details -

Ceramic Heater Technology Rollers

Our ceramic heater rollers are coated to provide uniform temperature at their surface, providing unmatched temperature uniformity and efficient heat transfer.

Benefits:

Temperature uniformity and efficient heat transfer.

Best Used For:

Heat transfer rolls.

View Details -

Charge Rollers

Charge rollers are used to transfer or project electrostatic charges.

Benefits:

Coated with thermal spray ceramics and other elastomeric material.

Best Used For:

Charge rollers are used to transfer or project electrostatic charges.

View Details -

Chevron or Herringbone Grooving

Spreader rollers grooving can take many forms including: herringbone pattern, chevron groove pattern, reverse taper configuration, and grooved rubber covers.

Benefits:

Improved web handling; wrinkle release

Best Used For:

Bowed roll and stretch roll applications.

View Details -

Coating Rollers

We design and manufacture coating rollers, which are involved in the application process of coating substrates such as: paper, fabric, film, foil, and more.

Benefits:

Apply even coat weight due to uniformity.

Best Used For:

Coating Rollers

View Details -

Cushioned Feed Rollers

We apply a tight tolerance wear-resistant covering to cushioned feed rollers, which are used to feed corrugated sheets through the line without damage.

Benefits:

Reduces product damage.

Best Used For:

Cushioned Feed Rollers

View Details -

Dancer Rollers

Dancer rollers are lightweight dead or live shaft idlers that sense changes in web tension. The lighter the weight, the more sensitive the rollers will be.

Benefits:

Assists in tention control on a web processing machine improving web tracking and increasing machine speeds.

Best Used For:

Controlling tension on a web.

View Details -

Deflector Rollers

Deflector rollers are used to turn webs and substrates.

Benefits:

Ozone and abrasion resistant, and will not degrade from oils or corrosive materials.

Best Used For:

Deflector Rollers

View Details -

Delivery Rollers

Delivery rollers aid in the delivery of substrates across web paths.

Benefits:

ffer various elastomeric compound roller coverings specific to application.

Best Used For:

Delivery Rollers

View Details -

Draw Rollers

Draw rollers are driven nip rollers that pull substrates.

Benefits:

Rollers are ozone and abrasion resistant, and will not degrade from oils or corrosive materials.

Best Used For:

Draw Rollers

View Details -

Drive Rollers

Drive rollers drive opposing nip rollers, allowing substrates to move through the web’s path.

Benefits:

Available in alloy steel, carbon steel, and stainless steel.

Best Used For:

Drive Rollers

View Details -

Dryer Drums

We coat dryer drums with durable, speciality formulated non-stick surfaces.

Benefits:

Allows dryer drums to run at higher speeds, with less sheet breaks and contamination or build up issues.

Best Used For:

Dryer Drums

View Details -

Embossing Back Up Rollers

Embossing back up rollers are used to create a nip under pressure, which creates a pattern on substrates.

Benefits:

Elastomeric roller coverings maximize performance.

Best Used For:

Embossing Back Up Rollers

View Details -

Embossing Rollers

Embossing rollers are used to create patterns on substrates.

Benefits:

Multiple surface finish roller bases for high performance and long term wear resistance.

Best Used For:

Embossing Rollers

View Details -

Expander Rollers

Expander rollers are used to expand the web by eliminating wrinkles. We offer various web spreading rollers including: bowed, crowned, concaved, and more.

Benefits:

Used to expand the web by eliminating wrinkles.

Best Used For:

Bowed roll and stretch roll applications.

View Details -

Film Conditioning Rollers

Film conditioning rollers are used for stretching, medium density overlays, and changing properties.

Benefits:

Film stretching without marking.

Best Used For:

These rollers are utilized primarily within the film industry.

View Details -

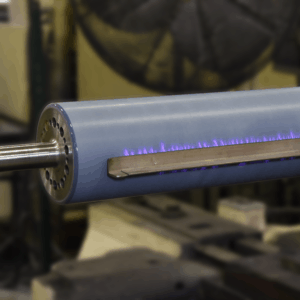

Flame Treating Back Up Rollers

Flame treating back up rollers are manufactured with corrosion and heat-resistant coatings as protection from the high temperatures during flame treating.

Benefits:

Longer service life in high temperatures.

Best Used For:

Flame Treating Back Up Rollers

View Details -

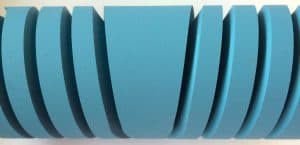

Foam Rollers

Foam rollers are manufactured from cellular material and used in a wide variety of applications and industries.

Benefits:

The "soft" core is supported by "tough" shell for improved wear resistance.

Best Used For:

Bump and splicing roll positions.

View Details -

Furnace Rollers

Furnace rollers are used to support webs and coils as they travel through ovens.

Benefits:

Products able to operate in temperatures over 600 F.

Best Used For:

Furnace Rollers

View Details -

Glue Rollers

Coating glue applicator rollers allows for easier cleanability during normal maintenance.

Benefits:

We have various coatings to match a solution to your glue or adhesive. Plasma Coatings 11,000 Series is a good choice.

Best Used For:

Glue Rollers

View Details -

Gravure Rollers

Gravure rollers are engraved or coated with a porous surface to contain ink, adhesive, or liquid until its application.

Benefits:

Liquid amounts depend on application.

Best Used For:

Gravure Rollers

View Details

Showing 1–30 of 74 results