-

Analytical Property Testing

Specific testing methods that include; Ash and Soxhlet Extraction Analysis, FT-IR Analysis by Diamond ATR, and FT-IR Spectrophotometric Analysis.

Benefits:

Identify root cause problems and limitiations from current performance.

Best Used For:

This is used to understand material composition and improve upon performance characteristics.

View Details -

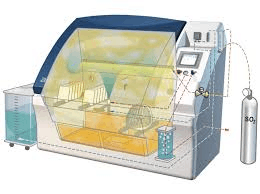

Ash and Soxhlet Extraction Analysis

Ash and soxhlet extraction analysis is one of the services we offer as part of our analytical property tests.

Benefits:

Identify root cause problems and limitiations from current performance.

Best Used For:

It is the process of transferring partially soluble components of a solid to the liquid phase using a Soxhlet extractor for material and composition analysis.

View Details -

Chemical Resistance Property Testing

These tests are conducted to determine chemical resistance characteristics of a covering, coating or finished part.

Benefits:

(1) Customer Media Immersion Testing (2) Volume, Weight and Hardness Change Data (3) Corrosion Resistance Testing (4) Solvent Wipe Testing

Best Used For:

Wide range of problem solving applications around corrosion protection.

View Details -

Coating Thickness and Condition

Through our on-site and in-house capabilities we assess coating thickness and condition, which is an important measurement when understanding resurfacing or reconditioning needs.

Benefits:

Identify current life of coating layer.

Best Used For:

Wide range of applications.

View Details -

Compression Load Deflection Testing

Compression Load Deflection Testing is one of the services we offer as part of our physical property tests.

Benefits:

This is useful in determing how a rubber covering will perform in a process condition.

Best Used For:

It is a nondestructive method for determining relationship between compressive load and deflection under load for vulcanized rubber. (ASTM D-575).

View Details -

Corrosion Resistance Testing

Corrosion Resistance Testing is one of the services we offer as part of our Chemical Resistance Property Testing.

Benefits:

Often this is an important test in determining the correct material and application process for coating or covering your parts in the application targeted.

Best Used For:

Wide range of applications.

View Details -

Dimension Checks for Journal and Body

Dimension checks for journal and bodies are reviews of a roller journal and body used to verify dimensions and advise on repairs or reconditioning as needed.

Benefits:

Re-store rollers to original state.

Best Used For:

Journal and Core Body Repair

View Details -

Durometer Measure

Durometer is the international standard used for measurement of rubber hardness in the roller industry and also refers to the instrument itself.

Benefits:

Measure and control roller hardness.

Best Used For:

This is a standard specification we define some products and servics with, providing documentation to our customers.

View Details -

Dynamic Abrasion Testing

Dynamic abrasion testing is one of the services we offer as part of our dynamic property testing.

Benefits:

This test is used in the pursuit of designing longer-lasting coverings and coatings.

Best Used For:

This test is used to determine resistance to wear of a particular coating or covering.

View Details -

Dynamic Property Testing

These tests are utilized to understand a coating or coverings response to pressure, heat and wear.

Benefits:

The tests include: Static Release Dynamic Abrasion Testing Pilot Testing Hysteresis (Heat Buildup) Testing

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

FT-IR Spectrophotometric Analysis

FT-IR spectrophotometric analysis is one of the services we offer as part of our analytical property testing.

Benefits:

This is used to understand material composition and peformance characteristics so that the optimal material and finish recommendation can be provided for a given application.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Hardness Testing

Harness testing is one of the services we offer as part of our physical property testing.

Benefits:

This type of testing helps us better understand current state and correlate the data to recommendations on better performing materials for the application.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Hysteresis (Heat Buildup) Testing

Hysteresis (heat build-up) testing is one of the services we offer as part of our dynamic property testing.

Benefits:

This test enables us to understand how the material will respond to heat and load under stress and how much its original performance characteristics will be maintained.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Mag. Particle Test

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) test for detecting surface and subsurface discontinuities in materials such as iron, nickel, cobalt, and some of their alloys.

Benefits:

Ensures product quality and uniformity.

Best Used For:

Often used as a quality verification process.

View Details -

Magna Flux Test

A magna flux test is a non-destructive testing (NDT) process for detecting surface, and subsurface, discontinuities in materials such as: iron, nickel, cobalt, and some of their alloys.

Benefits:

This process puts a magnetic field into the piece and the piece can be magnetized by direct or indirect magnetization.

Best Used For:

Often used as a quality verification process.

View Details -

Media Immersion Testing

Application media immersion testing is one of the services we offer as part of our Chemical Resistance Property Testing.

Benefits:

Chemical Resistance Property Testing.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

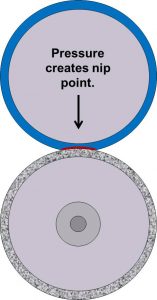

Nip Impressions

A nip impression is a measure of the uniformity of the pressure in a web processing nip. The pressure profile is sometimes referred to as a footprint.

Benefits:

This is useful in understanding how a machine is running or can run better. The company can provide a service in measuring the nip impression.

Best Used For:

Wide range of problem solving applications and analysis in the nip roll position of a web processing machine.

View Details -

Non Destructive Testing

Non destructive testing is analysis techniques used to evaluate the material of a roller or part without damaging it.

Benefits:

There is a wide variety of non-destructive tests utilized.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Ozone Resistance Testing

Ozone resistance testing is one of the services we offer as part of our physical property testing.

Benefits:

Ozone resistance testing

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Physical Property Testing

We offer a wide rand of physical property testing which enables us to determin material composition and performance expectations in order to optimize application solutions.

Benefits:

Compression Load Deflection Testing, Hardness Testing, Tensile, Elongation and Tear, Ozone Resistance, Surface Energy (Wettability), Surface Finish (Roughness), Thermal Conductivity

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

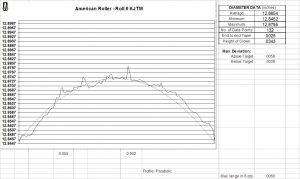

Rollers Run Out

Roller run out is a measurement of the roller’s surface roundness compared to the bearing surface.

Benefits:

Determine roller uniformity

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Solvent Wipe Testing

Solvent wipe testing is one of the services we offer as part of our chemical resistance property testing.

Benefits:

Chemical Resistance Property Testing.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Static Release

Static release testing is one of the services we offer as part of our dynamic property testing.

Benefits:

Determine static release properties.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Surface Energy (Wettability) Testing

Surface energy (wettability) testing is one of the services we offer as part of our physical property testing.

Benefits:

Evaluate surface characteristics.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Surface Finish (Roughness) Testing

Surface finish (roughness) testing is one of the services we offer as part of our physical property testing.

Benefits:

Determine surface roughness (RA)

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Temperature Profile

A service we provide that records and inteprets the temperatures of a roll while in use.

Benefits:

Determine temperature levels in process.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Thermal Conductivity Testing

Thermal conductivity testing is one of the services we offer as part of our physical property testing.

Benefits:

Determin thermal conductivity.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Ultra Sonic Test

An ultra sonic test is the testing of a material to determine any flaws within it.

Benefits:

Determine flaws.

Best Used For:

Wide range of problem solving applications and analysis.

View Details

Showing all 28 results