-

Accumulator Rollers

Accumulator roller are used in film and metal handling lines.

Benefits:

Ozone and abrasion resistant, and do not degrade from oils or corrosive materials.

Best Used For:

Accumulator Rollers

View Details -

Back Up Rollers

Back up rollers are used in various applications to provide stability and thermal enhancements.

Benefits:

We offer various covers for our rollers for optimal coverage.

Best Used For:

Back Up Rollers

View Details -

Bridle Rollers

Bridle rollers drive strips through the production line.

Benefits:

Ozone and abrasion resistant, and will not degrade from oils or corrosive materials.

Best Used For:

Bridle Rollers

View Details -

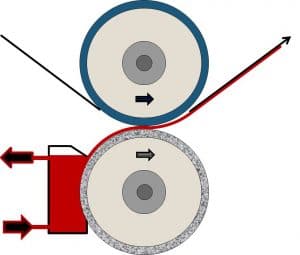

Calender Rollers

Calender rollers, which are usually configured in pairs, are used to gauge a web to a predetermined thickness by running the web through a controlled gap.

Benefits:

Calender rollers are series of hard pressure rollers that are used on-line or off-line to form or smooth a sheet of material like paper or plastic film.

Best Used For:

Calendar Rollers

View Details -

Carbon Fiber Rollers

Rollers that are primarily used when both high strength and low weight are needed. We also manufacture and coat carbon fiber unwind and rewind shafts and reel spools.

Benefits:

Referred to as our Valcom product; unique in the industry with bonding techniques that enable us to be only supplier to provide hard facing and ceramic coatings to a ground finish on carbon fiber rolls!

Best Used For:

Carbon fiber rolls.

View Details -

Ceramic Heater Technology Rollers

Our ceramic heater rollers are coated to provide uniform temperature at their surface, providing unmatched temperature uniformity and efficient heat transfer.

Benefits:

Temperature uniformity and efficient heat transfer.

Best Used For:

Heat transfer rolls.

View Details -

Chemical Coater Applicator Rollers

Chemical coater application rollers are used to apply chemicals to metals.

Benefits:

Rollers have a longer life span because of their ability to withstand wear.

Best Used For:

Chemical Coater Applicator Rollers

View Details -

Chevron or Herringbone Grooving

Spreader rollers grooving can take many forms including: herringbone pattern, chevron groove pattern, reverse taper configuration, and grooved rubber covers.

Benefits:

Improved web handling; wrinkle release

Best Used For:

Bowed roll and stretch roll applications.

View Details -

Coating Rollers

We design and manufacture coating rollers, which are involved in the application process of coating substrates such as: paper, fabric, film, foil, and more.

Benefits:

Apply even coat weight due to uniformity.

Best Used For:

Coating Rollers

View Details -

Dancer Rollers

Dancer rollers are lightweight dead or live shaft idlers that sense changes in web tension. The lighter the weight, the more sensitive the rollers will be.

Benefits:

Assists in tention control on a web processing machine improving web tracking and increasing machine speeds.

Best Used For:

Controlling tension on a web.

View Details -

Delivery Rollers

Delivery rollers aid in the delivery of substrates across web paths.

Benefits:

ffer various elastomeric compound roller coverings specific to application.

Best Used For:

Delivery Rollers

View Details -

Dip Tank Coater Rollers

Dip tank coater rollers hold webs/coils in chemicals when painting them.

Benefits:

Rollers are able to resist swelling and wear from chemicals for longer life spans.

Best Used For:

Dip Tank Coater Rollers

View Details -

Drive Rollers

Drive rollers drive opposing nip rollers, allowing substrates to move through the web’s path.

Benefits:

Available in alloy steel, carbon steel, and stainless steel.

Best Used For:

Drive Rollers

View Details -

EGL Conductor Rollers

EGL conductor rollers are used in electro galvanizing lines and need to be corrosion and abrasion-resistant.

Benefits:

Solution to reduce wear.

Best Used For:

EGL Conductor Rollers

View Details -

Embossing Back Up Rollers

Embossing back up rollers are used to create a nip under pressure, which creates a pattern on substrates.

Benefits:

Elastomeric roller coverings maximize performance.

Best Used For:

Embossing Back Up Rollers

View Details -

Embossing Rollers

Embossing rollers are used to create patterns on substrates.

Benefits:

Multiple surface finish roller bases for high performance and long term wear resistance.

Best Used For:

Embossing Rollers

View Details -

ETL Conductor Rollers

Electrolytic tinplate lines (ETL) conductor rollers need to be resistant to corrosion, abrasion, and arc-induced pitting.

Benefits:

We offer wear-resistant solutions.

Best Used For:

ETL Conductor Rollers

View Details -

Flame Treating Back Up Rollers

Flame treating back up rollers are manufactured with corrosion and heat-resistant coatings as protection from the high temperatures during flame treating.

Benefits:

Longer service life in high temperatures.

Best Used For:

Flame Treating Back Up Rollers

View Details -

Flattening Rollers

Flattening or Leveler rollers require high strength and durability as they are used in the level or “flattening” of steel or other hard metal or cement/asphalt surfaces.

Benefits:

Longer service life.

Best Used For:

Flattening Rollers

View Details -

Furnace Rollers

Furnace rollers are used to support webs and coils as they travel through ovens.

Benefits:

Products able to operate in temperatures over 600 F.

Best Used For:

Furnace Rollers

View Details -

Gravure Rollers

Gravure rollers are engraved or coated with a porous surface to contain ink, adhesive, or liquid until its application.

Benefits:

Liquid amounts depend on application.

Best Used For:

Gravure Rollers

View Details -

Leveler Rollers

Leveler rollers are used in metal tension leveling lines to pull metal through tension levelers.

Benefits:

Longer service life.

Best Used For:

Leveler Rollers

View Details -

LIMISTAT

Limistat is a series of electrically conductive rubber covered rollers designed to aid in dissipating static produced by webs.

Benefits:

Reduce static build-up in high speed web applications.

Best Used For:

Limistat functions best in high-speed webs that suffer from static electricity buildup.

View Details -

-

Nip Rollers

Our nip rollers are available in alloy steel, carbon steel, and stainless steel. Nip rollers are also known as pinch rollers and by various other names.

Benefits:

Proper selection affects product quality and line speeds.

Best Used For:

They are used to press two or more sheets together to form a laminated product.

View Details -

Oiler Rollers

Oiler rollers are used to apply oil, normally to metal.

Benefits:

Rollers are able to withstand swelling and wear from contact with oils to provide longer life spans.

Best Used For:

Oiler Rollers

View Details -

Paint Applicator Rollers

Paint Applicator Rollers are used to apply paint directly to metal coils.

Benefits:

Rollers are manufactured to be abrasion-resistant and have a longer service life.

Best Used For:

Paint Applicator Rollers

View Details -

Pass Rollers

Pass rollers are used in the steel industry and it is important to utilize the correct materials of construction to ensure peformance and long lasting life.

Benefits:

Longer service life.

Best Used For:

Pass Rollers

View Details -

Pegasus II

The Pegasus II utilizes the same technology as the Pegasus I but features a more wear-resistant urethane outer covering.

Benefits:

These rollers are designed to compress and rebound back to its original size without generating heat.

Best Used For:

Lay on roll position.

View Details -

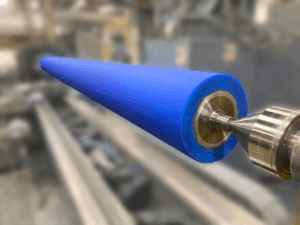

Pellex

Pellex offers specially formulated proprietary coverings and coatings that offer excellent abrasion resistance and overall force resistance which allows accurate delivery of the strands to the cutting unit, producing consistent, uniform pellets.

Benefits:

Specially formulated covering has outstanding abrasion resistance which allows for accurate delivery of the strands to the cutting unit, producing consistent, uniform pellets.

Best Used For:

Pelletizing equipment

View Details

Showing 1–30 of 52 results