-

Adhesive Pans

Adhesive pans are used to catch excess adhesive during manufacturing.

Benefits:

Coatings designed to improve pan cleanabilty and extend the life.

Best Used For:

A wide variety of industries.

View Details -

Agitator Blades

Agitator blades are used to blend a wide range of materials.

Benefits:

Wear-resistant and non-stick coatings to the blade surfaces to enhance performance.

Best Used For:

A wide variety of industries.

View Details -

Anti-static Tank

Our anti-static tanks are coated with anti-static coatings to prevent static from hindering process flow and causing severe build-up on the tank’s walls.

Benefits:

Improve service life.

Best Used For:

A wide variety of industries.

View Details -

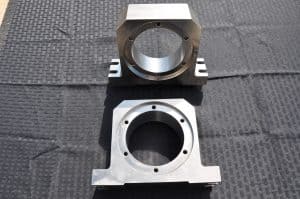

Bearing Surfaces

We coat bearing surfaces with wear-resistant coatings in order to have longer run-times per component and protection from high pressures and rough environments.

Benefits:

Extend service life.

Best Used For:

A wide variety of industries.

View Details -

Bin

Bins are great storage solutions, prevent wear, and provide easy cleanability.

Benefits:

We offer numerous coatings designed to protect bins during various applications.

Best Used For:

A wide variety of industries.

View Details -

Boiler Tubes

We apply corrosion and wear resistant-metal and ceramic solutions to boiler tubes to protect their surfaces from hot oxidation and erosion from fine particles.

Benefits:

Extend service life.

Best Used For:

Boilers in a wide variety of process industries.

View Details -

Burners

Burners are used in corrosive and abrasive environments.

Benefits:

Coat burners with a wide range of alloys that address the issues of corrosion and abrasion.

Best Used For:

A wide variety of industries.

View Details -

Chemicals - Solid and Liquid

We apply engineered coating solutions based on specific corrosion concerns in each chemical environment, which protects our products and their life spans.

Benefits:

Extend service life.

Best Used For:

A wide variety of industries.

View Details -

Chrome Plating

Standard Chrome plating for new cores as well as re-chroming of used cores.

Benefits:

Corrosion protection and other key surface protection properties

Best Used For:

Heat transfer and chill rolls; other surfaces requiring corrosion protection.

View Details -

Chrome Plus +

Chrome Plus is a environmentally friendly carbide coating replacement for Chrome. With equivalent price, performance, surface finish and thermal transfer properties.

Benefits:

Green replacement for Chrome. A scratch resistant and repair capable coating for use in a wide variety of applications.

Best Used For:

Heat transfer and chill rolls and other metals surfaces.

View Details -

Chute

We apply non-stick, low-friction, and anti-static coatings to chutes, which improves flow and down-time without the need of vibrators or air cannons.

Benefits:

Improves flow and down-time without the need of vibrators or air cannons.

Best Used For:

A wide variety of industries.

View Details -

Coal Riffles

Coal Riffles help balance the combustible flow to the burners in coal plants.

Benefits:

Coat coal riffles to protect them from wear on their surfaces and edges.

Best Used For:

Coal industry.

View Details -

Combustion Wire Metallizing

In this process, various metal wire is fed into an oxygen-acetylene gas mixture. It is then in a molten state and sprayed onto the part being processed.

Benefits:

This most basic of coating techniques is limited by maximum temperature attainable and the universe of materials that can be set.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Corrosion Protection

We have a wide range of coating options to help address corrosion. Pptions include the application of thermally sprayed metals and polymers or a combination of the two technologies.

Benefits:

In many instances, our coatings can address the corrosive problem while providing secondary benefits such as release or improved surface hardness promoting erosion resistance.

Best Used For:

A wide range of corrosion protection applications.

View Details -

Cyclones

Cyclones are used to remove dust and/or gas from processing operations and separating the particles.

Benefits:

Apply wear-resistant coatings to improve cost.

Best Used For:

A wide variety of industries.

View Details -

Cylinders or liners

We apply engineered corrosion-resistant coatings to cylinders and liners for natural gas during the manufacturing process to provide protection and reduce wear.

Benefits:

Provide protection and reduce wear.

Best Used For:

A wide variety of industries.

View Details -

Dead Plates

Dead plates are used to convey material.

Benefits:

Coating combinations to address issues likes: wear, friction, chemicals, sticking, and more.

Best Used For:

A wide variety of industries.

View Details -

Ductwork

Ductwork is used to remove corrosive gases and heat from processing.

Benefits:

Engineer specialized composite coatings to combat high temperature corrosion and wear.

Best Used For:

A wide variety of industries.

View Details -

Electric Arc

This process uses materials in wire form, but the heat source is the arcing of two electrically conductive wires. Material is melted and propelled on the part at a greater velocity than metallizing.

Benefits:

Higher temperatures allow for an increased source of base materials, faster rates of deposition, and improved bond and coating density.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Electric Arc Furnace

We engineer and apply coating solutions that significantly increase the life of water-cooled electric arc furnace duct work.

Benefits:

Solutions are applicable on-site

Best Used For:

A wide variety of industries.

View Details -

Electrically Conductive

Our electrically conductive coatings can be applied to: anti-static idler rollers, anti-static tanks, bins, chutes, silo coatings, and web grounding rollers for charged webs.

Benefits:

Electrical conductivity.

Best Used For:

These coatings are also used in medical and electronic applications.

View Details -

Electrically Insulated

Our electrically insulated coatings can be applied to: bins, chutes, corona treater rollers, silo coatings, web insulated tanks, and support rollers for electrically charged processes.

Benefits:

Electrical insulation.

Best Used For:

They are also used in medical and electronic coating applications.

View Details -

Electrostatic

Through our electrostatic systems we are able to apply: fluorocarbons, fluoropolymers, silicones, epoxies, and Teflon® industrial coatings.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

Expandable sleeves

Expandable sleeves are used in various markets.

Benefits:

Sleeves have elastomeric coverings, solving issues with increased cooling and reduced static build-up.

Best Used For:

A wide variety of industries.

View Details -

Fan Blades

Gas mixed with fine particles can cause wear or unbalance when they stick to fan blades.

Benefits:

Apply protective coatings to prevent wear and improve self-cleaning.

Best Used For:

A wide variety of industries.

View Details -

Fluidizing Beds

We offer coating solutions that provide wear-resistant, low-friction, non-stick surfaces for fluidizing beds, which deal with difficult to handle materials.

Benefits:

Wear-resistant, low-friction, non-stick surfaces with difficult to handle materials.

Best Used For:

We offer coating solutions that provide wear-resistant, low-friction, non-stick surfaces for fluidizing beds, which deal with difficult to handle materials.

View Details -

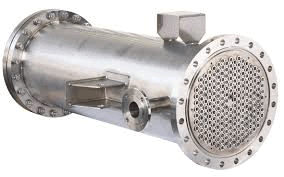

Heat Exchanger

Heat exchangers are used in corrosive and abrasive environments.

Benefits:

Coat them with a wide range of alloys that address the issues of corrosion and abrasion.

Best Used For:

A wide range of industries and applications

View Details -

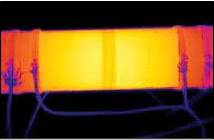

Heated Piping

Heated piping is coated to maintain uniform temperature across the face of a pipe.

Benefits:

Apply patended SmartHeat technology to keep temperatures uniform.

Best Used For:

A wide range of industries and applications

View Details -

High Pressure Separator Vessels

High pressure separator vessels commonly have issues with corrosion and fouling.

Benefits:

Engineer and apply coatings that can address corrosion and fouling.

Best Used For:

A wide range of industries and applications

View Details -

Holding Tanks

We engineer and apply a variety of low friction, high release, and easily cleaned coatings for holding tank interiors.

Benefits:

Extend service life.

Best Used For:

A wide range of industries and applications

View Details

Showing 1–30 of 77 results