-

Actuator Shafts

Actuator shafts are either manfuactured new or refurbished back original dimensions. Often these shafts are coated with corrosions or wear resistant coatings.

Benefits:

Corrosions or wear resistant coatings.

Best Used For:

A wide variety of industries.

View Details -

Adhesive Pans

Adhesive pans are used to catch excess adhesive during manufacturing.

Benefits:

Coatings designed to improve pan cleanabilty and extend the life.

Best Used For:

A wide variety of industries.

View Details -

Agitator Blades

Agitator blades are used to blend a wide range of materials.

Benefits:

Wear-resistant and non-stick coatings to the blade surfaces to enhance performance.

Best Used For:

A wide variety of industries.

View Details -

Air Bars

Air bars are used to control alignment and directional change of substrates.

Benefits:

Coatings improve performance, eliminate build-up, and extend their life span.

Best Used For:

A wide variety of industries.

View Details -

Air Shafts

Air shafts are used in processing for winding and unwinding substrates.

Benefits:

Apply high friction coatings to reduce slippage and increase performance.

Best Used For:

A wide variety of industries.

View Details -

Anti-static Tank

Our anti-static tanks are coated with anti-static coatings to prevent static from hindering process flow and causing severe build-up on the tank’s walls.

Benefits:

Improve service life.

Best Used For:

A wide variety of industries.

View Details -

Balers

Balers are used to collect reclaim of trimmed product for recycling and disposal.

Benefits:

Coat bailers to combat erosion, contamination, and product build-up.

Best Used For:

A wide variety of industries.

View Details -

Bead Rings

We coat bead rings used in the tire making process to provide anti-stick and wear resistance properties improving products and extending the life of components.

Benefits:

Extend service life.

Best Used For:

Tire making process.

View Details -

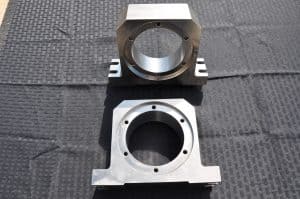

Bearing Surfaces

We coat bearing surfaces with wear-resistant coatings in order to have longer run-times per component and protection from high pressures and rough environments.

Benefits:

Extend service life.

Best Used For:

A wide variety of industries.

View Details -

Belt Cutting Anvils

Belt cutting anvils cut belts to the proper size to be used in tire manufacturing.

Benefits:

Coat belt cutting anvils to provide low friction and high release.

Best Used For:

Tire making process.

View Details -

Bin

Bins are great storage solutions, prevent wear, and provide easy cleanability.

Benefits:

We offer numerous coatings designed to protect bins during various applications.

Best Used For:

A wide variety of industries.

View Details -

Boiler Tubes

We apply corrosion and wear resistant-metal and ceramic solutions to boiler tubes to protect their surfaces from hot oxidation and erosion from fine particles.

Benefits:

Extend service life.

Best Used For:

Boilers in a wide variety of process industries.

View Details -

Building Drums

Building drums are used in the tire industry in the tire building process.

Benefits:

Drums are coated for release and wear resistance using a full range of coatings.

Best Used For:

Tire making process.

View Details -

Burners

Burners are used in corrosive and abrasive environments.

Benefits:

Coat burners with a wide range of alloys that address the issues of corrosion and abrasion.

Best Used For:

A wide variety of industries.

View Details -

Chemicals - Solid and Liquid

We apply engineered coating solutions based on specific corrosion concerns in each chemical environment, which protects our products and their life spans.

Benefits:

Extend service life.

Best Used For:

A wide variety of industries.

View Details -

Chute

We apply non-stick, low-friction, and anti-static coatings to chutes, which improves flow and down-time without the need of vibrators or air cannons.

Benefits:

Improves flow and down-time without the need of vibrators or air cannons.

Best Used For:

A wide variety of industries.

View Details -

Coal Riffles

Coal Riffles help balance the combustible flow to the burners in coal plants.

Benefits:

Coat coal riffles to protect them from wear on their surfaces and edges.

Best Used For:

Coal industry.

View Details -

Conveyors

Roller conveyors are used when shrink-wrap is needed.

Benefits:

We manufacture cores with durable, dual composite, non-stick coatings making it safe to use scrapers.

Best Used For:

A wide variety of industries.

View Details -

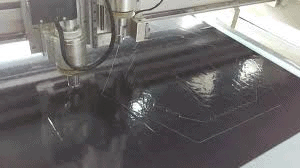

Cutter Tables

Cutter tables are often used to cut woven material to size.

Benefits:

Coat cutter tables with durable, dual composite, non-stick coatings to resist de-lamination.

Best Used For:

Non-woven manufacturing.

View Details -

Cyclones

Cyclones are used to remove dust and/or gas from processing operations and separating the particles.

Benefits:

Apply wear-resistant coatings to improve cost.

Best Used For:

A wide variety of industries.

View Details -

Cylinders or liners

We apply engineered corrosion-resistant coatings to cylinders and liners for natural gas during the manufacturing process to provide protection and reduce wear.

Benefits:

Provide protection and reduce wear.

Best Used For:

A wide variety of industries.

View Details -

Dead Plates

Dead plates are used to convey material.

Benefits:

Coating combinations to address issues likes: wear, friction, chemicals, sticking, and more.

Best Used For:

A wide variety of industries.

View Details -

Die Plates

Die plates are used in manufacturing plastic molds.

Benefits:

Durable non-stick coatings for various plastics removing the need to mold non-stick applications.

Best Used For:

A wide variety of industries.

View Details -

Dispensers

Dispensers are used to apply various materials both liquid and solid.

Benefits:

Coat dispensers with non-stick corrosion-resistant coatings to improve efficiency.

Best Used For:

A wide variety of industries.

View Details -

Diverter Plates

We apply engineered coatings to diverter plates during manufacturing for easy cleanability.

Benefits:

Easy cleanability.

Best Used For:

Diverter plates are utilized within the printing industry.

View Details -

Diverter Wedge

We apply engineered coatings to diverter wedges during manufacturing for easy cleanability. Diverter wedges are utilized within the printing industry.

Benefits:

Easy cleanability.

Best Used For:

Diverter wedges are utilized within the printing industry.

View Details -

Doctor Chamber

Doctor chambers are used to hold doctor blades, which control the metering of ink being transferred.

Benefits:

Coatings act as an ink repellent for easy cleaning.

Best Used For:

A wide variety of industries.

View Details -

DSB Sheet Rings

These components are used in the tire and rubber manufacturing process.

Benefits:

Rings are coated with release (non-stick) and wear resistance coatings.

Best Used For:

Tire and rubber manufacturing process

View Details -

Ductwork

Ductwork is used to remove corrosive gases and heat from processing.

Benefits:

Engineer specialized composite coatings to combat high temperature corrosion and wear.

Best Used For:

A wide variety of industries.

View Details -

Electric Arc Furnace

We engineer and apply coating solutions that significantly increase the life of water-cooled electric arc furnace duct work.

Benefits:

Solutions are applicable on-site

Best Used For:

A wide variety of industries.

View Details

Showing 1–30 of 107 results