-

Centerless Grinding

Centerless grinding is process that uses abrasive cutting to remove material. This differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece.

Benefits:

Workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece.

Best Used For:

A wide variety of applications.

View Details -

Chevron or Herringbone Grooving

Spreader rollers grooving can take many forms including: herringbone pattern, chevron groove pattern, reverse taper configuration, and grooved rubber covers.

Benefits:

Improved web handling; wrinkle release

Best Used For:

Bowed roll and stretch roll applications.

View Details -

ID Grinding

We perform Internal Diameter Grinding on complex parts.

Benefits:

Smooth internal diameter surface finish.

Best Used For:

A wide variety of applications.

View Details -

Knurled and Ground finishes

Available in a variety of aluminum and steel, our knurled and ground finishes are available for the manufacturing and repair of custom converting rollers.

Benefits:

Custom finish solutions.

Best Used For:

A wide variety of applications.

View Details -

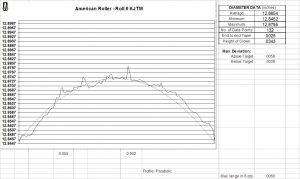

Machined Crowns

Roller crowning is intended to ensure proper web alignment and helps minimize the effects of deflection. Materials include several types of aluminum and steel.

Benefits:

Minimize the effects of deflection.

Best Used For:

A wide variety of applications.

View Details -

Mirror Finishing

Chrome plating is used where a “mirror” finish is needed.

Benefits:

Mirror finishing is a very smooth surface and can either decrease or increase web/roller friction.

Best Used For:

A wide variety of applications.

View Details -

Re-Grinding

Re-grinding is often done to remove existing plating, for example chrome plating, from converting rollers and industrial parts due to scratches, dents, and existing worn areas.

Benefits:

Remove existing material due to scratches, dents, and existing worn areas.

Best Used For:

A wide variety of applications.

View Details -

Reverse Tapers (concave crowns)

Spreader rollers’ grooving can take many forms including: herringbone pattern, chevron groove pattern, and reverse tapers (also known as concave crowns).

Benefits:

Custom finish solutions.

Best Used For:

A wide variety of applications.

View Details -

Rollers Crowning

Roll crowning is intended to ensure proper web alignment and helps minimize the effects of deflection.

Benefits:

Minimize the effects of deflection.

Best Used For:

A wide variety of applications.

View Details -

Rollers Grooving

Roller grooving is available in herringbone, chevron, and spiral groove patterns.

Benefits:

Improved web handling; wrinkle release

Best Used For:

A wide variety of applications.

View Details -

Spiral Grooving for Air Entrapment Removal

Spreader rollers’ grooving can take many forms including: spiral grooving, chevron groove pattern, reverse taper configuration, and grooved rubber covers.

Benefits:

Improved web handling; wrinkle release

Best Used For:

A wide variety of applications.

View Details

Showing all 11 results