-

Bag Making Pull Rollers

Bag making pull rollers are used to transfer pre-cut bags to separation and printing.

Benefits:

These rollers have grooved wear-resistant coverings to withstand inertia.

Best Used For:

Bag Making Pull Rollers

View Details -

Chevron or Herringbone Grooving

Spreader rollers grooving can take many forms including: herringbone pattern, chevron groove pattern, reverse taper configuration, and grooved rubber covers.

Benefits:

Improved web handling; wrinkle release

Best Used For:

Bowed roll and stretch roll applications.

View Details -

Cushioned Feed Rollers

We apply a tight tolerance wear-resistant covering to cushioned feed rollers, which are used to feed corrugated sheets through the line without damage.

Benefits:

Reduces product damage.

Best Used For:

Cushioned Feed Rollers

View Details -

Dryer Drums

We coat dryer drums with durable, speciality formulated non-stick surfaces.

Benefits:

Allows dryer drums to run at higher speeds, with less sheet breaks and contamination or build up issues.

Best Used For:

Dryer Drums

View Details -

Embossing Back Up Rollers

Embossing back up rollers are used to create a nip under pressure, which creates a pattern on substrates.

Benefits:

Elastomeric roller coverings maximize performance.

Best Used For:

Embossing Back Up Rollers

View Details -

Embossing Rollers

Embossing rollers are used to create patterns on substrates.

Benefits:

Multiple surface finish roller bases for high performance and long term wear resistance.

Best Used For:

Embossing Rollers

View Details -

Furnace Rollers

Furnace rollers are used to support webs and coils as they travel through ovens.

Benefits:

Products able to operate in temperatures over 600 F.

Best Used For:

Furnace Rollers

View Details -

Lead-in Lead Out Rollers to dryer sections

Lead in and lead out rollers are also used to lead to dryer sections during manufacturing.

Benefits:

They are engineered with durable, non-stick, easily cleaned surfaces.

Best Used For:

Lead-in Lead Out Rollers to dryer sections

View Details -

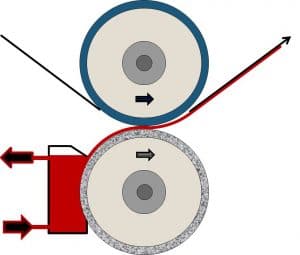

Nip/Laminator Rollers

Laminator rollers are also known as nip rollers and by various other names.

Benefits:

Proper selection affects product quality and line speeds.

Best Used For:

They are used to press two or more sheets together to form a laminated product.

View Details -

Press Rollers

Press rolls are used in a wide variety of industries and applications.

Benefits:

These rollers are made out of many different substrates and coverings or coatings.

Best Used For:

Press Rollers

View Details -

Pressure Rollers

Pressure rolls are used in the corrugating industry and are typically chrome or hard faced rolls. Often times these rolls are also crowned for deflection.

Benefits:

Increase machine speeds and longer service life.

Best Used For:

Pressure Rollers

View Details -

Pull Rollers

Pull rollers are driven nip rollers that pull subtrants.

Benefits:

Rollers are ozone and abrasion resistant, and will not degrade from oils or corrosive materials.

Best Used For:

Pull Rollers

View Details -

Sealing Rollers

We offer a wide variety of covering and coatings for sealing rollers including: non-stick, corrosion-resistant, and high temperature-resistant solutions.

Benefits:

Non-stick, corrosion-resistant, and high temperature-resistant surface properaties.

Best Used For:

Sealing Rollers

View Details -

Support Rollers for Electrically Charged Processes

Support rollers for electrically charged processes require electrical insulation.

Benefits:

Offer various coverings and coatings to be tailored to your application.

Best Used For:

Support Rollers for Electrically Charged Processes

View Details

Showing all 14 results