-

Corrosion Protection

We have a wide range of coating options to help address corrosion. Pptions include the application of thermally sprayed metals and polymers or a combination of the two technologies.

Benefits:

In many instances, our coatings can address the corrosive problem while providing secondary benefits such as release or improved surface hardness promoting erosion resistance.

Best Used For:

A wide range of corrosion protection applications.

View Details -

Electrically Conductive

Our electrically conductive coatings can be applied to: anti-static idler rollers, anti-static tanks, bins, chutes, silo coatings, and web grounding rollers for charged webs.

Benefits:

Electrical conductivity.

Best Used For:

These coatings are also used in medical and electronic applications.

View Details -

Electrically Insulated

Our electrically insulated coatings can be applied to: bins, chutes, corona treater rollers, silo coatings, web insulated tanks, and support rollers for electrically charged processes.

Benefits:

Electrical insulation.

Best Used For:

They are also used in medical and electronic coating applications.

View Details -

Low Friction

Reduce the cleanup and buildup of such materials as starches, paints, adhesives, latex, rubber, food, paper, ice, sugar, resins, tapes, inks.

Benefits:

Extremely wear resistant and long lasting.

Best Used For:

Hard base onto your part and then impregnate one of our Low COF release agents into that coating.

View Details -

Non & Conductive Coatings

Conductive and non-conductive coatings are used promote or limit the flow of heat or electrical current into or away from the object that is coated.

Benefits:

Wide variety of metal, metal alloy, carbide matrix, ceramic, and polymer coatings available with these properties as well as combination coatings composed of thermal spray and polymer coatings.

Best Used For:

Conductive and non-conductive surface properties.

View Details -

Release & Cleanability

Certified DuPont Licensed Industrial Applicator (DLA), user of Whitford coatings, and we blend our own, resulting in leading the industry in release coating services for a variety of industries.

Benefits:

Non-stick and release properties on surfaces.

Best Used For:

Our coatings reduce the clean up and build-up of such materials as starches, paints, adhesives, latex, rubber, food, paper, ice, sugar, resins, tapes, inks.

View Details -

Surface Traction

By using a high traction coating, slippage is eliminated resulting in a more consistent performance resulting in improved machine traction.

Benefits:

Ensure tight starts, eliminate slippage and wrinkles, and improve web tracking and tension control.

Best Used For:

Traction control in on web processing machines.

View Details -

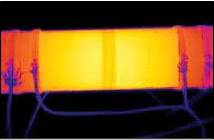

Thermal Conductive

Thermally Conductive and Semi-Conductive Coatings do not significantly impede the flow of heat in or out of the substrate that is coated.

Benefits:

Provide other unique surface properties such as cut and abrasion resistance or release.

Best Used For:

These are used in applications where rapid heat transfer is important, such as heated and chilled rollers.

View Details -

Thermal Insulating

Thermal Insulating coatings prevent the substrate from giving up internal heat or absorbing heat from an external source.

Benefits:

Temperature uniformity and efficient heat transfer.

Best Used For:

A wide variety of applications.

View Details -

Wear & Abrasion

Parts wear due to exposure to numerous types of wear; abrasion erosion, fretting, adhesive wear, fatigue and combinations of multiple wear.

Benefits:

Allows the user to design equipment made of a lighter and/or less expensive material and enhance the surface for better wear by using coatings.

Best Used For:

A wide variety of applications.

View Details

Showing all 10 results