-

Actuator Shafts

Actuator shafts are either manfuactured new or refurbished back original dimensions. Often these shafts are coated with corrosions or wear resistant coatings.

Benefits:

Corrosions or wear resistant coatings.

Best Used For:

A wide variety of industries.

View Details -

Air Shafts

Air shafts are used in processing for winding and unwinding substrates.

Benefits:

Apply high friction coatings to reduce slippage and increase performance.

Best Used For:

A wide variety of industries.

View Details -

Balers

Balers are used to collect reclaim of trimmed product for recycling and disposal.

Benefits:

Coat bailers to combat erosion, contamination, and product build-up.

Best Used For:

A wide variety of industries.

View Details -

Bead Rings

We coat bead rings used in the tire making process to provide anti-stick and wear resistance properties improving products and extending the life of components.

Benefits:

Extend service life.

Best Used For:

Tire making process.

View Details -

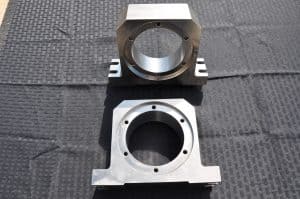

Bearing Surfaces

We coat bearing surfaces with wear-resistant coatings in order to have longer run-times per component and protection from high pressures and rough environments.

Benefits:

Extend service life.

Best Used For:

A wide variety of industries.

View Details -

Belt Cutting Anvils

Belt cutting anvils cut belts to the proper size to be used in tire manufacturing.

Benefits:

Coat belt cutting anvils to provide low friction and high release.

Best Used For:

Tire making process.

View Details -

Bin

Bins are great storage solutions, prevent wear, and provide easy cleanability.

Benefits:

We offer numerous coatings designed to protect bins during various applications.

Best Used For:

A wide variety of industries.

View Details -

Building Drums

Building drums are used in the tire industry in the tire building process.

Benefits:

Drums are coated for release and wear resistance using a full range of coatings.

Best Used For:

Tire making process.

View Details -

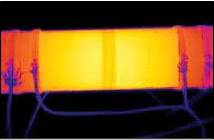

Chrome Plating

Standard Chrome plating for new cores as well as re-chroming of used cores.

Benefits:

Corrosion protection and other key surface protection properties

Best Used For:

Heat transfer and chill rolls; other surfaces requiring corrosion protection.

View Details -

Chrome Plus +

Chrome Plus is a environmentally friendly carbide coating replacement for Chrome. With equivalent price, performance, surface finish and thermal transfer properties.

Benefits:

Green replacement for Chrome. A scratch resistant and repair capable coating for use in a wide variety of applications.

Best Used For:

Heat transfer and chill rolls and other metals surfaces.

View Details -

Chute

We apply non-stick, low-friction, and anti-static coatings to chutes, which improves flow and down-time without the need of vibrators or air cannons.

Benefits:

Improves flow and down-time without the need of vibrators or air cannons.

Best Used For:

A wide variety of industries.

View Details -

Combustion Wire Metallizing

In this process, various metal wire is fed into an oxygen-acetylene gas mixture. It is then in a molten state and sprayed onto the part being processed.

Benefits:

This most basic of coating techniques is limited by maximum temperature attainable and the universe of materials that can be set.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Corrosion Protection

We have a wide range of coating options to help address corrosion. Pptions include the application of thermally sprayed metals and polymers or a combination of the two technologies.

Benefits:

In many instances, our coatings can address the corrosive problem while providing secondary benefits such as release or improved surface hardness promoting erosion resistance.

Best Used For:

A wide range of corrosion protection applications.

View Details -

Dead Plates

Dead plates are used to convey material.

Benefits:

Coating combinations to address issues likes: wear, friction, chemicals, sticking, and more.

Best Used For:

A wide variety of industries.

View Details -

DSB Sheet Rings

These components are used in the tire and rubber manufacturing process.

Benefits:

Rings are coated with release (non-stick) and wear resistance coatings.

Best Used For:

Tire and rubber manufacturing process

View Details -

Electric Arc

This process uses materials in wire form, but the heat source is the arcing of two electrically conductive wires. Material is melted and propelled on the part at a greater velocity than metallizing.

Benefits:

Higher temperatures allow for an increased source of base materials, faster rates of deposition, and improved bond and coating density.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Electric Arc Furnace

We engineer and apply coating solutions that significantly increase the life of water-cooled electric arc furnace duct work.

Benefits:

Solutions are applicable on-site

Best Used For:

A wide variety of industries.

View Details -

Electrically Conductive

Our electrically conductive coatings can be applied to: anti-static idler rollers, anti-static tanks, bins, chutes, silo coatings, and web grounding rollers for charged webs.

Benefits:

Electrical conductivity.

Best Used For:

These coatings are also used in medical and electronic applications.

View Details -

Electrically Insulated

Our electrically insulated coatings can be applied to: bins, chutes, corona treater rollers, silo coatings, web insulated tanks, and support rollers for electrically charged processes.

Benefits:

Electrical insulation.

Best Used For:

They are also used in medical and electronic coating applications.

View Details -

Electrostatic

Through our electrostatic systems we are able to apply: fluorocarbons, fluoropolymers, silicones, epoxies, and Teflon® industrial coatings.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

Expandable sleeves

Expandable sleeves are used in various markets.

Benefits:

Sleeves have elastomeric coverings, solving issues with increased cooling and reduced static build-up.

Best Used For:

A wide variety of industries.

View Details -

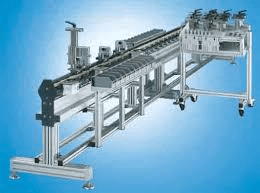

Fabric Cutter Tables

We offer coating solutions for fabric cutter tables to provide easier clean ability and low friction when in contact with green rubber during your application.

Benefits:

Easier clean ability and low friction

Best Used For:

Tire and rubber manufacturing process

View Details -

Fluidizing Beds

We offer coating solutions that provide wear-resistant, low-friction, non-stick surfaces for fluidizing beds, which deal with difficult to handle materials.

Benefits:

Wear-resistant, low-friction, non-stick surfaces with difficult to handle materials.

Best Used For:

We offer coating solutions that provide wear-resistant, low-friction, non-stick surfaces for fluidizing beds, which deal with difficult to handle materials.

View Details -

HVOF

In this process metal particles actually travel faster than the speed of sound, generating the best bond strengths, density and hardness of all our processes.

Benefits:

HVOF does not reach temperatures that are attainable with plasma processes so materials such as ceramicsare not processed with this technique.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Laser Cladding

Laser cladding is an additive manufacturing process that utilizes a laser to metallurgically bond performance coatings to a product’s base material.

Benefits:

The process uses the laser to create a melt pool of the base material. The coating material is introduced into this melt pool in either powder or wire form.

Best Used For:

A wide range of cladding applications; including small footprint applications.

View Details -

Liquid Dispersion

Liquid dispersion is a polymer coating process technique used in a wide variety of applications.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

Low Friction

Reduce the cleanup and buildup of such materials as starches, paints, adhesives, latex, rubber, food, paper, ice, sugar, resins, tapes, inks.

Benefits:

Extremely wear resistant and long lasting.

Best Used For:

Hard base onto your part and then impregnate one of our Low COF release agents into that coating.

View Details -

Machine Frame

We deisgn, engineer and apply coatings to machine frames for wear and corrosion resistance to extend their life spans.

Benefits:

Service is provided on-site.

Best Used For:

A wide range of industries and applications

View Details -

Molds

We manufacture durable, wear-resistant, release coatings for molds, and various other molding equipment, to resist and protect against product build-up.

Benefits:

Resist and protect against product build-up.

Best Used For:

A wide range of industries and applications

View Details -

Nickel Plating

Electroless Nickel plating offers some advantages over chrome plating. It has a better resistance to corrosion with relatively thinner coatings than chrome.

Benefits:

Electroless Nickel plating in the as-plated condition has a hardness of approximately 50Rc. It can be heat treated by baking to a hardness of approximately 70Rc.

Best Used For:

Electroless Nickel plating can be applied to aluminum and steel.

View Details

Showing 1–30 of 70 results