-

Actuator Shafts

Actuator shafts are either manfuactured new or refurbished back original dimensions. Often these shafts are coated with corrosions or wear resistant coatings.

Benefits:

Corrosions or wear resistant coatings.

Best Used For:

A wide variety of industries.

View Details -

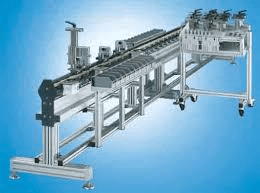

Air Bars

Air bars are used to control alignment and directional change of substrates.

Benefits:

Coatings improve performance, eliminate build-up, and extend their life span.

Best Used For:

A wide variety of industries.

View Details -

Air Shafts

Air shafts are used in processing for winding and unwinding substrates.

Benefits:

Apply high friction coatings to reduce slippage and increase performance.

Best Used For:

A wide variety of industries.

View Details -

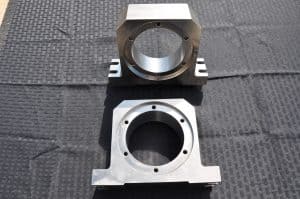

Bearing Surfaces

We coat bearing surfaces with wear-resistant coatings in order to have longer run-times per component and protection from high pressures and rough environments.

Benefits:

Extend service life.

Best Used For:

A wide variety of industries.

View Details -

Bin

Bins are great storage solutions, prevent wear, and provide easy cleanability.

Benefits:

We offer numerous coatings designed to protect bins during various applications.

Best Used For:

A wide variety of industries.

View Details -

Chrome Plating

Standard Chrome plating for new cores as well as re-chroming of used cores.

Benefits:

Corrosion protection and other key surface protection properties

Best Used For:

Heat transfer and chill rolls; other surfaces requiring corrosion protection.

View Details -

Chrome Plus +

Chrome Plus is a environmentally friendly carbide coating replacement for Chrome. With equivalent price, performance, surface finish and thermal transfer properties.

Benefits:

Green replacement for Chrome. A scratch resistant and repair capable coating for use in a wide variety of applications.

Best Used For:

Heat transfer and chill rolls and other metals surfaces.

View Details -

Chute

We apply non-stick, low-friction, and anti-static coatings to chutes, which improves flow and down-time without the need of vibrators or air cannons.

Benefits:

Improves flow and down-time without the need of vibrators or air cannons.

Best Used For:

A wide variety of industries.

View Details -

Combustion Wire Metallizing

In this process, various metal wire is fed into an oxygen-acetylene gas mixture. It is then in a molten state and sprayed onto the part being processed.

Benefits:

This most basic of coating techniques is limited by maximum temperature attainable and the universe of materials that can be set.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Corrosion Protection

We have a wide range of coating options to help address corrosion. Pptions include the application of thermally sprayed metals and polymers or a combination of the two technologies.

Benefits:

In many instances, our coatings can address the corrosive problem while providing secondary benefits such as release or improved surface hardness promoting erosion resistance.

Best Used For:

A wide range of corrosion protection applications.

View Details -

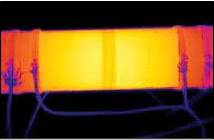

Dryer Drums

We coat dryer drums with durable, speciality formulated non-stick surfaces.

Benefits:

Allows dryer drums to run at higher speeds, with less sheet breaks and contamination or build up issues.

Best Used For:

Dryer Drums

View Details -

Electric Arc

This process uses materials in wire form, but the heat source is the arcing of two electrically conductive wires. Material is melted and propelled on the part at a greater velocity than metallizing.

Benefits:

Higher temperatures allow for an increased source of base materials, faster rates of deposition, and improved bond and coating density.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Electric Arc Furnace

We engineer and apply coating solutions that significantly increase the life of water-cooled electric arc furnace duct work.

Benefits:

Solutions are applicable on-site

Best Used For:

A wide variety of industries.

View Details -

Electrically Conductive

Our electrically conductive coatings can be applied to: anti-static idler rollers, anti-static tanks, bins, chutes, silo coatings, and web grounding rollers for charged webs.

Benefits:

Electrical conductivity.

Best Used For:

These coatings are also used in medical and electronic applications.

View Details -

Electrically Insulated

Our electrically insulated coatings can be applied to: bins, chutes, corona treater rollers, silo coatings, web insulated tanks, and support rollers for electrically charged processes.

Benefits:

Electrical insulation.

Best Used For:

They are also used in medical and electronic coating applications.

View Details -

Electrostatic

Through our electrostatic systems we are able to apply: fluorocarbons, fluoropolymers, silicones, epoxies, and Teflon® industrial coatings.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

HVOF

In this process metal particles actually travel faster than the speed of sound, generating the best bond strengths, density and hardness of all our processes.

Benefits:

HVOF does not reach temperatures that are attainable with plasma processes so materials such as ceramicsare not processed with this technique.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Laser Cladding

Laser cladding is an additive manufacturing process that utilizes a laser to metallurgically bond performance coatings to a product’s base material.

Benefits:

The process uses the laser to create a melt pool of the base material. The coating material is introduced into this melt pool in either powder or wire form.

Best Used For:

A wide range of cladding applications; including small footprint applications.

View Details -

Liquid Dispersion

Liquid dispersion is a polymer coating process technique used in a wide variety of applications.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

Low Friction

Reduce the cleanup and buildup of such materials as starches, paints, adhesives, latex, rubber, food, paper, ice, sugar, resins, tapes, inks.

Benefits:

Extremely wear resistant and long lasting.

Best Used For:

Hard base onto your part and then impregnate one of our Low COF release agents into that coating.

View Details -

Machine Frame

We deisgn, engineer and apply coatings to machine frames for wear and corrosion resistance to extend their life spans.

Benefits:

Service is provided on-site.

Best Used For:

A wide range of industries and applications

View Details -

Mills

We manufacture wear-resistant, non-stick corrosion-resistant coatings to improve the efficiency and down time of mills.

Benefits:

Improve the efficiency and down time of mills.

Best Used For:

A wide range of industries and applications

View Details -

Non & Conductive Coatings

Conductive and non-conductive coatings are used promote or limit the flow of heat or electrical current into or away from the object that is coated.

Benefits:

Wide variety of metal, metal alloy, carbide matrix, ceramic, and polymer coatings available with these properties as well as combination coatings composed of thermal spray and polymer coatings.

Best Used For:

Conductive and non-conductive surface properties.

View Details -

Plasma Spray

In this process we use various gasses that are ignited by an electric arc. Temperatures can rise up to 30,000° F while the part temperature remains at less than 200°F.

Benefits:

Particle velocity is greater than in the other four systems. One of the benefits of using this system is the high heat, which can process materials with high melting points (including ceramics).

Best Used For:

Utilized to apply metal and ceramic based coatings.

View Details -

Plasma Transferred Arc

We manufacture and utlize plasma transferred arc welding or cladding systems to provide wear and corrosion resistant coatings or claddings.

Benefits:

Provide a protective wear layer or rebuild parts back to original dimensional integrity.

Best Used For:

This technology is used to rebuild surfaces back to original dimensional integrity.

View Details -

Plating

Plating often involves two process materials and/or steps where the first material bonds to the base material and serves as the primer for finish plating.

Benefits:

A wide range of surface property enhancements.

Best Used For:

A wide variety of applications.

View Details -

Powder Coat

The powder coat process is used in many of our polmyer coating processes.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

Screens

Screens and screening systems are often subjected to wear, corrosion, and build-up.

Benefits:

Extend service life and prevent product build up.

Best Used For:

A wide range of industries and applications

View Details -

Storage Equipment/Tanks

Storage equipment, like tanks, are used to store manufacturing material.

Benefits:

Offer a variety of durable non-stick and wear-resistant coatings for tank interiors.

Best Used For:

A wide range of industries and applications

View Details -

Surface Traction

By using a high traction coating, slippage is eliminated resulting in a more consistent performance resulting in improved machine traction.

Benefits:

Ensure tight starts, eliminate slippage and wrinkles, and improve web tracking and tension control.

Best Used For:

Traction control in on web processing machines.

View Details

Showing 1–30 of 37 results