Flexible Rope

PT-MAT™ -Flexible rope for oxyacetylene welding is made by extruding a mixture of tungsten carbide / NiCrBSi powder around a solid nickel wire core.

The welded coating will contain roughly 65% tungsten carbide and 35% matrix alloy.

The tungsten carbides will be angular cast tungsten carbides (FTC at about 2300 HV0.1) or spherical fused tungsten carbide (SFTC at about 2900 HV0.1).

The NiCrBSi alloy will melt at a lower temperature (1850° F average) while encapsulating the hard tungsten

carbide and will leave a clean surface.

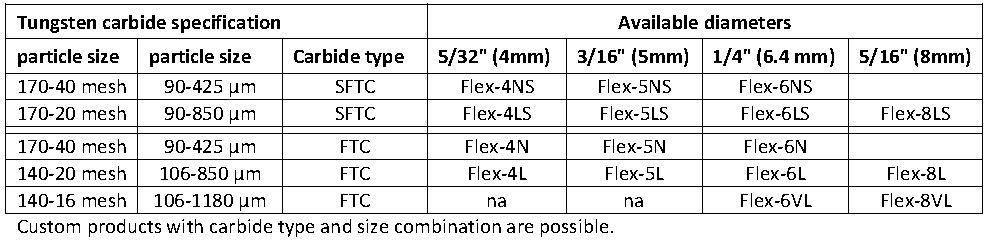

PT-MAT™ – Flex is available in different diameters either with FTC or SFTC, other custom compositions can be

made to order.

Hardness

PT-MAT™ Flex is recommended for wear protection on oil drilling parts such as stabilizers, fixed cutter bits and in other industries on mixer components, processing screws.

Most austenitic and ferritic carbon steels can be readily overlaid, proceed with caution on stainless steel alloys not recommended on cast iron.

Hardness :Matrix : 40-45 HRc. Fused / cast tungsten carbide (FTC) : 2100-2400 HV0.1

Matrix : 40-45 HRc. Spherical fused tungsten carbide (SFTC) : 2600-3500 HV0.1

Product Availability

Packaging

On plastic spools 22 lbs (10 kg) or 44 lbs (20 kg).

To view pdf version, click here.