Chilled iron rolls have been the standard for years in the Paper and Rubber industries, while hardened steel rolls have been the standard in the Metals industry and in many Converting applications. Both types can cross over all industries and the choice is often based on personal preference and what may have been the original equipment specification. Today, with fewer foundries producing chilled iron rolls, deliveries are often very long. This contributes heavily to the growing utilization and advances in hardened steel rolls.

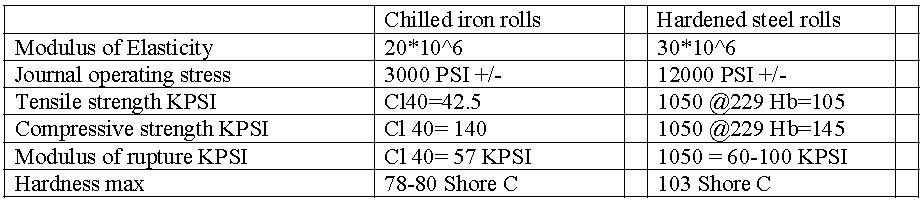

Strength of Chilled Iron vs. Steel:

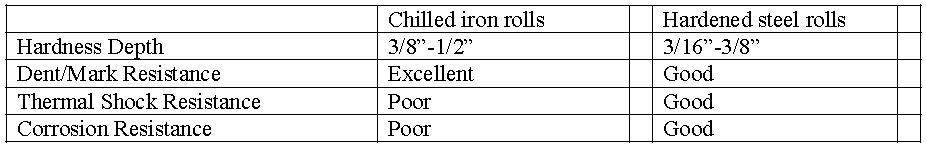

Surface Characteristics:

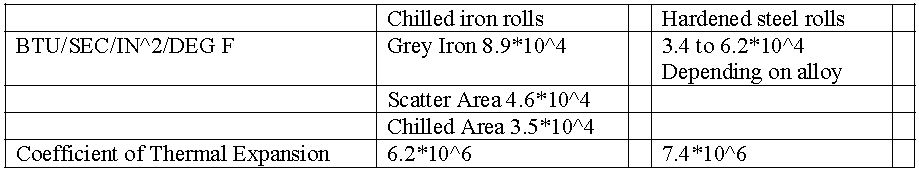

Rolls Heat Transfer:

Temperature profile with Chilled or Heated Systems:

A constant, uniform temperature is very critical to nipped applications. A slight difference in temperature can produce disastrous results. A 16” diameter steel roll with a temperature difference of only 10°F can result in .001” change in diameter! Yet often on heated rolls, where we see heat sinks at the ends of the roll, it is not uncommon to see temperatures as much as 30-40°F higher than under the web path. To complicate things more, the temperatures are often decreasing as the fluid crosses the web, creating a taper profile in the web area with high ends of unequal diameter. Imagine the problems this can cause for a coating application or a product requiring a uniform nip pressure.

In chilled iron rolls, these figures can be approximately 20% less; but the temperature profile is often dependent on drilled holes located well below the surface of the roller. These holes are subject to variations in thickness of grey iron, scatter, and chill areas; which all transfer heat at different rates. (See charts) The casting process for chilled iron rolls produces an area of clear chill between ¼” and ¾”; with an area of heavy scatter mix of chill and gray iron from 1-3” and grey iron below this. This makes drilling these rolls difficult and requires the drilled holes to be well below the surface of the roll normally between 1.5” and 4”, below the surface. Chill depth is normally better on smaller diameter rolls, as they chill more rapidly during casting process.

Today for heating rolls we have options which give us much better temperature profiles. Electrically heated roll technology combined with the use of heat pipes deliver very uniform temperature profiles. A heat load capacity is designed into the roll to produce desired results on different web thickness or materials. American Roller Company manufactures a patented, heated roll system called Thermalon®, which excels in this area. The Thermalon® roll system is one of the most dependable designs available and requires very little service work. Any required service can normally be done on site, eliminating the need to send the roll back to the manufacturer.

Another option for heat transfer is the double shell roll. These rolls can also provide uniform results, when properly designed. The best heat transfer is obtained with thin outer shells that have a shrink fit over a spiral baffle that transfers load to a heavy inner wall. These rolls give good results when properly designed for fluid velocity and volume internally.

The Thermalon® and double shell steel rolls above will provide the best performance when we have the following conditions:

- Long diameter to length ratios (over 10 to 1)

- High load applied to the roll, with limited room to increase diameter

- When a lower moment of inertia is required or desired

- Where more corrosion resistant materials and/or alloys are required

- In applications where rapid temperature chances cause thermal shock

- Any time engraved rolls are required

Roll Surveys:

As demands on equipment change, it is important to review these critical process rolls. A roll survey can be performed to help determine process weaknesses and identify areas for improvement. You should be sure chilled or heated roll systems are not a limiting factor that may be reducing throughput or causing unnecessary rework and scrap in your business. When these limiting factors are studied, Engineers can offer solutions by recommending the use of improved, state of the art technology and engineered products. Customized Roll Surveys are available from American Roller Company, at a very reasonable cost. These surveys are tailored to your needs and can be set up through an American Roller Account Manager or by calling a Regional Customer Service Representative.

By: Bill Field

Roll Product Manager

American Roller Company

To view pdf version click here.