One of the causes for inconsistent pellets starts with the top and/or bottom feed rollers within the pelletizing system.

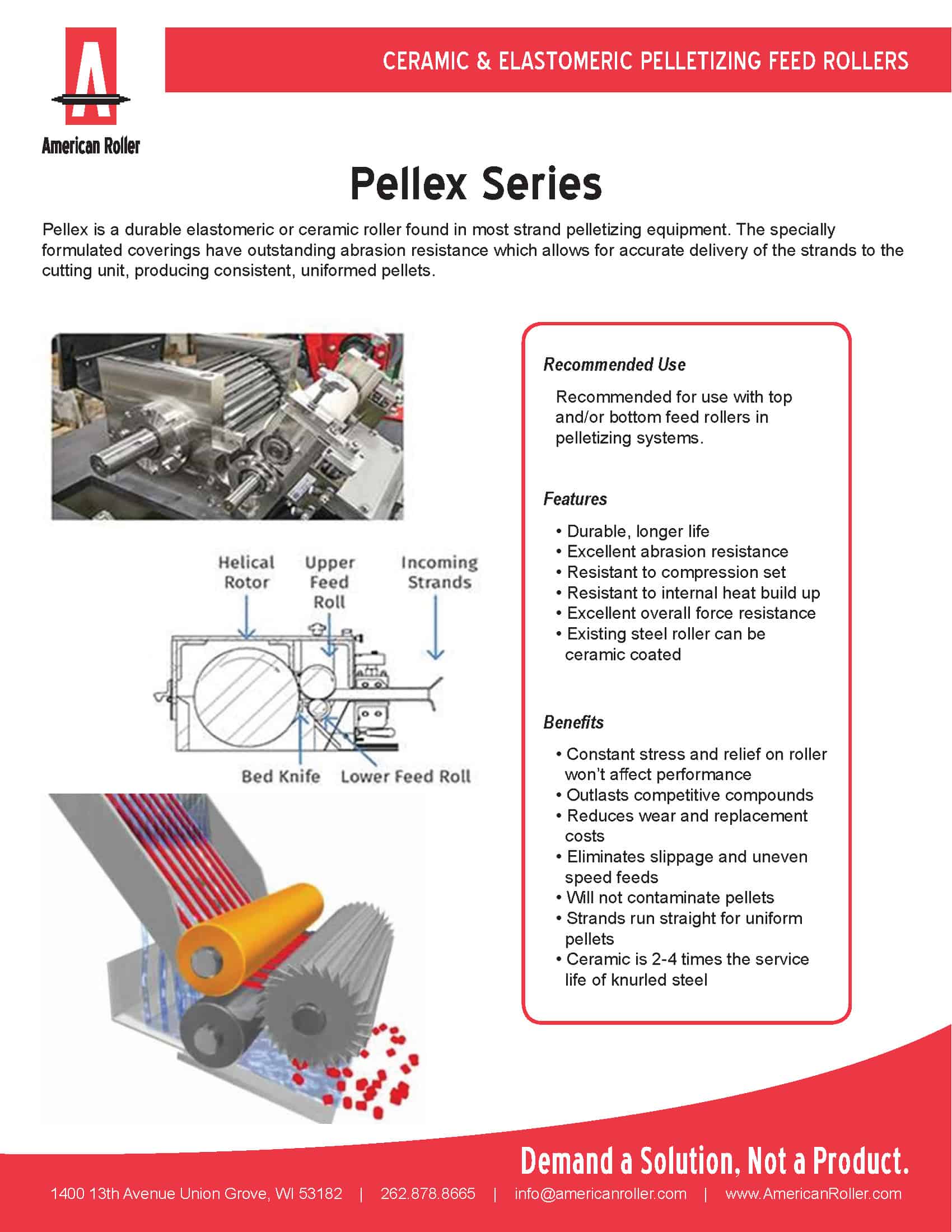

When the coefficient of friction on the top and bottom feed rollers is not properly designed for pelletizing, you may start experiencing non-uniform sized pellets. When this occurs, the surface of one or both feed rollers typically has begun degrading from consistent use. A degraded surface finish of the feed roller(s) will experience a loss of grip necessary to feed incoming strands evenly into the helical rotor.

In addition to the surface finish of both feed rolls degrading, the upper feed roll may also be exposed to damage from the helical rotor.

Specifically designed for pelletizing equipment, our Pellex series was formulated to have outstanding abrasion and cut resistance.

If you are experiencing inconsistent, non-uniform pellets, give us a call today

to speak with an account manager who will be able to help!

| Contact Us |

Download the full Pellex Sell Sheet HERE