-

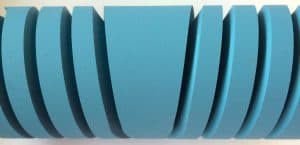

Accumulator Rollers

Accumulator roller are used in film and metal handling lines.

Benefits:

Ozone and abrasion resistant, and do not degrade from oils or corrosive materials.

Best Used For:

Accumulator Rollers

View Details -

Acid Flushing

Acid flushing breaks down and flushes out the internal corrosion deposits and blockages in heat transfer rollers to improve flowrates and improve thermal conductivity.

Benefits:

Improves efficiencies in heat transfer rates.

Best Used For:

Heat Transfer and Chill Rolls

View Details -

Actuator Shafts

Actuator shafts are either manfuactured new or refurbished back original dimensions. Often these shafts are coated with corrosions or wear resistant coatings.

Benefits:

Corrosions or wear resistant coatings.

Best Used For:

A wide variety of industries.

View Details -

Adhesive Pans

Adhesive pans are used to catch excess adhesive during manufacturing.

Benefits:

Coatings designed to improve pan cleanabilty and extend the life.

Best Used For:

A wide variety of industries.

View Details -

Air Bars

Air bars are used to control alignment and directional change of substrates.

Benefits:

Coatings improve performance, eliminate build-up, and extend their life span.

Best Used For:

A wide variety of industries.

View Details -

Air Shafts

Air shafts are used in processing for winding and unwinding substrates.

Benefits:

Apply high friction coatings to reduce slippage and increase performance.

Best Used For:

A wide variety of industries.

View Details -

Analytical Property Testing

Specific testing methods that include; Ash and Soxhlet Extraction Analysis, FT-IR Analysis by Diamond ATR, and FT-IR Spectrophotometric Analysis.

Benefits:

Identify root cause problems and limitiations from current performance.

Best Used For:

This is used to understand material composition and improve upon performance characteristics.

View Details -

Anilox Rollers

Anilox rollers are engraved or coated with a porous surface to contain ink, adhesive, or liquid until its application.

Benefits:

Uniform printing.

Best Used For:

Printing ink distribution

View Details -

Anti-static Idler Rollers

Anti-static idler rollers are manufactured and used to reduce static electricity build-up.

Benefits:

Reduce statis electricity on high speed web processing machines.

Best Used For:

They are used within the paper, film, foil, and plastic industries.

View Details -

Anvil Rollers

Anvil rollers, also known as slitter rollers, are hardened rollers on which a circular cutter rides in order to part, slit or perforate the web.

Benefits:

Some slitter rollers are multi-grooved over which a razor or razors are mounted to slit the web.

Best Used For:

Anvil rollers are used for slitting (separating) applications.

View Details -

ARCOSTRETCHER

Arcostretcher rollers are available in single, double, quad or six groove patterns.

Benefits:

Ideal for handling very thin substrates and allows converters to run these thinner substrates at lower tensions and higher line speeds for better productivity.

Best Used For:

Bowed roll and stretch roll applications.

View Details -

ARCOTRON

The industry leader and standard for a complete product line of corona treater coverings.

Benefits:

Arcotron specialty rollers comes in eight (8) specific solutions for use in elastomer, epoxy, and ceramic treater applications. With 100% corona treater testing prior to shipment, you are ensured the highest quality and longest lasting treater roll with the strongest warranty on the market.

Best Used For:

Corona Treater applications

View Details -

ASME Heat Transfer Rollers

We design, manufacturer, and repair high quality, custom ASME heat transfer rollers per ASME Section VIII, Division 1.

Benefits:

This is a pressure tested vessel with stamped approvals; ensuring safe operating procedures.

Best Used For:

Heat transfer and chill rolls.

View Details -

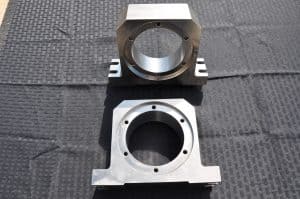

Assembly

In providing turnkey solutions to our customers, we are often asked to also provide fabrication and assembly services associated with our machining and covering solutions.

Benefits:

On stop shop capability to solve manufacturing problems.

Best Used For:

We provide this service along with program management of such projects.

View Details -

Back Up Rollers

Back up rollers are used in various applications to provide stability and thermal enhancements.

Benefits:

We offer various covers for our rollers for optimal coverage.

Best Used For:

Back Up Rollers

View Details -

Bag Making Pull Rollers

Bag making pull rollers are used to transfer pre-cut bags to separation and printing.

Benefits:

These rollers have grooved wear-resistant coverings to withstand inertia.

Best Used For:

Bag Making Pull Rollers

View Details -

Balancing

Two plane and 3 plane balancing is a common request. Detailed balance reports are provided post-balancing, ensuring that roller and parts perform in an optimal manner.

Benefits:

This is increasingly important in today's high running machine speeds.

Best Used For:

Roll and machine balance.

View Details -

Bearing Surfaces

We coat bearing surfaces with wear-resistant coatings in order to have longer run-times per component and protection from high pressures and rough environments.

Benefits:

Extend service life.

Best Used For:

A wide variety of industries.

View Details -

Bin

Bins are great storage solutions, prevent wear, and provide easy cleanability.

Benefits:

We offer numerous coatings designed to protect bins during various applications.

Best Used For:

A wide variety of industries.

View Details -

Bowed Rollers

Bowed rollers address web handling and wrinkling problems in a wide variety of materials and web speeds.

Benefits:

Can be rubber covered or steel segmented and can have a fixed or adjustable bow.

Best Used For:

Bowed roll and stretch roll applications.

View Details -

Box Repair

We offer roller and crating repairs on storage and transport boxes, which are repaired and refurbished with our in-house capabilities.

Benefits:

Re-store transportation containers reducing cost.

Best Used For:

Box Repair

View Details -

Broaching

Broaching is a machining process that uses a toothed tool to remove material. Typical workpieces include small to medium-sized castings, forgings, screw machine parts, and stampings.

Benefits:

Maximum machining flexibility.

Best Used For:

Broaching is used when precision machining is required, especially for odd shapes. Commonly machined surfaces include circular and non-circular holes, splines, keyways, and flat surfaces.

View Details -

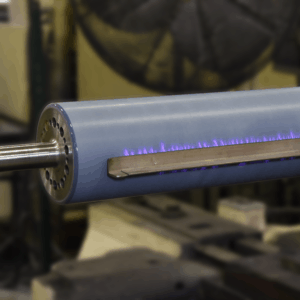

Building-Up & Re-machining Journals

Building up (welding) and re-machining is usually done if a journal is worn, damaged, or simply bent- ultimately impacting the performance of web processing.

Benefits:

Re-store journals to original and critical dimensions; thus reducing replacement costs.

Best Used For:

Journal Repair

View Details -

Bump Rollers

Bump rollers are manufactured and used for splicing and/or joining two webs together.

Benefits:

Used within the paper, film, foil, and plastic industries.

Best Used For:

Bump Rollers

View Details -

Calender Rollers

Calender rollers, which are usually configured in pairs, are used to gauge a web to a predetermined thickness by running the web through a controlled gap.

Benefits:

Calender rollers are series of hard pressure rollers that are used on-line or off-line to form or smooth a sheet of material like paper or plastic film.

Best Used For:

Calendar Rollers

View Details -

Carbon Fiber Rollers

Rollers that are primarily used when both high strength and low weight are needed. We also manufacture and coat carbon fiber unwind and rewind shafts and reel spools.

Benefits:

Referred to as our Valcom product; unique in the industry with bonding techniques that enable us to be only supplier to provide hard facing and ceramic coatings to a ground finish on carbon fiber rolls!

Best Used For:

Carbon fiber rolls.

View Details -

Cast Film Extrusion Rollers

Our cast film extrusion rollers are manufactured and used to cast molten plastic to film.

Benefits:

Durable coverings with release and non-marking characteristics.

Best Used For:

These rollers are standardly used within the plastic industry.

View Details -

Centerless Grinding

Centerless grinding is process that uses abrasive cutting to remove material. This differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece.

Benefits:

Workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece.

Best Used For:

A wide variety of applications.

View Details

Showing 1–30 of 306 results