-

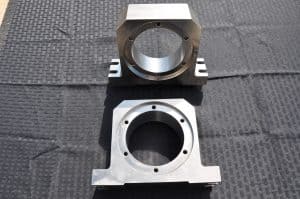

5-Axis Machining

We offer 5-axis machining of parts. This service is when our CNC machine is needed to approach the part from multiple directions.

Benefits:

Maximum machining flexibility.

Best Used For:

A wide range of machining needs from production to job shop applications.

View Details -

Accumulator Rollers

Accumulator roller are used in film and metal handling lines.

Benefits:

Ozone and abrasion resistant, and do not degrade from oils or corrosive materials.

Best Used For:

Accumulator Rollers

View Details -

Acid Flushing

Acid flushing breaks down and flushes out the internal corrosion deposits and blockages in heat transfer rollers to improve flowrates and improve thermal conductivity.

Benefits:

Improves efficiencies in heat transfer rates.

Best Used For:

Heat Transfer and Chill Rolls

View Details -

Actuator Shafts

Actuator shafts are either manfuactured new or refurbished back original dimensions. Often these shafts are coated with corrosions or wear resistant coatings.

Benefits:

Corrosions or wear resistant coatings.

Best Used For:

A wide variety of industries.

View Details -

Adhesive Pans

Adhesive pans are used to catch excess adhesive during manufacturing.

Benefits:

Coatings designed to improve pan cleanabilty and extend the life.

Best Used For:

A wide variety of industries.

View Details -

Air Bars

Air bars are used to control alignment and directional change of substrates.

Benefits:

Coatings improve performance, eliminate build-up, and extend their life span.

Best Used For:

A wide variety of industries.

View Details -

Air Shafts

Air shafts are used in processing for winding and unwinding substrates.

Benefits:

Apply high friction coatings to reduce slippage and increase performance.

Best Used For:

A wide variety of industries.

View Details -

Analytical Property Testing

Specific testing methods that include; Ash and Soxhlet Extraction Analysis, FT-IR Analysis by Diamond ATR, and FT-IR Spectrophotometric Analysis.

Benefits:

Identify root cause problems and limitiations from current performance.

Best Used For:

This is used to understand material composition and improve upon performance characteristics.

View Details -

Anilox Rollers

Anilox rollers are engraved or coated with a porous surface to contain ink, adhesive, or liquid until its application.

Benefits:

Uniform printing.

Best Used For:

Printing ink distribution

View Details -

Anti-static Idler Rollers

Anti-static idler rollers are manufactured and used to reduce static electricity build-up.

Benefits:

Reduce statis electricity on high speed web processing machines.

Best Used For:

They are used within the paper, film, foil, and plastic industries.

View Details -

Anvil Rollers

Anvil rollers, also known as slitter rollers, are hardened rollers on which a circular cutter rides in order to part, slit or perforate the web.

Benefits:

Some slitter rollers are multi-grooved over which a razor or razors are mounted to slit the web.

Best Used For:

Anvil rollers are used for slitting (separating) applications.

View Details -

Assembly

In providing turnkey solutions to our customers, we are often asked to also provide fabrication and assembly services associated with our machining and covering solutions.

Benefits:

On stop shop capability to solve manufacturing problems.

Best Used For:

We provide this service along with program management of such projects.

View Details -

Back Up Rollers

Back up rollers are used in various applications to provide stability and thermal enhancements.

Benefits:

We offer various covers for our rollers for optimal coverage.

Best Used For:

Back Up Rollers

View Details -

Balancing

Two plane and 3 plane balancing is a common request. Detailed balance reports are provided post-balancing, ensuring that roller and parts perform in an optimal manner.

Benefits:

This is increasingly important in today's high running machine speeds.

Best Used For:

Roll and machine balance.

View Details -

Bearing Surfaces

We coat bearing surfaces with wear-resistant coatings in order to have longer run-times per component and protection from high pressures and rough environments.

Benefits:

Extend service life.

Best Used For:

A wide variety of industries.

View Details -

Box Repair

We offer roller and crating repairs on storage and transport boxes, which are repaired and refurbished with our in-house capabilities.

Benefits:

Re-store transportation containers reducing cost.

Best Used For:

Box Repair

View Details -

Breast Rollers

Breast rollers are used within the paper industry in the first phase of forming a sheet of paper.

Benefits:

Coated breast rollers for corrosion and wear-resistance.

Best Used For:

Breast Rollers

View Details -

Broaching

Broaching is a machining process that uses a toothed tool to remove material. Typical workpieces include small to medium-sized castings, forgings, screw machine parts, and stampings.

Benefits:

Maximum machining flexibility.

Best Used For:

Broaching is used when precision machining is required, especially for odd shapes. Commonly machined surfaces include circular and non-circular holes, splines, keyways, and flat surfaces.

View Details -

Building-Up & Re-machining Journals

Building up (welding) and re-machining is usually done if a journal is worn, damaged, or simply bent- ultimately impacting the performance of web processing.

Benefits:

Re-store journals to original and critical dimensions; thus reducing replacement costs.

Best Used For:

Journal Repair

View Details -

Bump Rollers

Bump rollers are manufactured and used for splicing and/or joining two webs together.

Benefits:

Used within the paper, film, foil, and plastic industries.

Best Used For:

Bump Rollers

View Details -

Ceramic Heater Technology Rollers

Our ceramic heater rollers are coated to provide uniform temperature at their surface, providing unmatched temperature uniformity and efficient heat transfer.

Benefits:

Temperature uniformity and efficient heat transfer.

Best Used For:

Heat transfer rolls.

View Details -

Charge Rollers

Charge rollers are used to transfer or project electrostatic charges.

Benefits:

Coated with thermal spray ceramics and other elastomeric material.

Best Used For:

Charge rollers are used to transfer or project electrostatic charges.

View Details -

Chemical Resistance Property Testing

These tests are conducted to determine chemical resistance characteristics of a covering, coating or finished part.

Benefits:

(1) Customer Media Immersion Testing (2) Volume, Weight and Hardness Change Data (3) Corrosion Resistance Testing (4) Solvent Wipe Testing

Best Used For:

Wide range of problem solving applications around corrosion protection.

View Details -

Chrome Plating

Standard Chrome plating for new cores as well as re-chroming of used cores.

Benefits:

Corrosion protection and other key surface protection properties

Best Used For:

Heat transfer and chill rolls; other surfaces requiring corrosion protection.

View Details -

Chrome Plus +

Chrome Plus is a environmentally friendly carbide coating replacement for Chrome. With equivalent price, performance, surface finish and thermal transfer properties.

Benefits:

Green replacement for Chrome. A scratch resistant and repair capable coating for use in a wide variety of applications.

Best Used For:

Heat transfer and chill rolls and other metals surfaces.

View Details -

Chute

We apply non-stick, low-friction, and anti-static coatings to chutes, which improves flow and down-time without the need of vibrators or air cannons.

Benefits:

Improves flow and down-time without the need of vibrators or air cannons.

Best Used For:

A wide variety of industries.

View Details -

CNC Lathes

The utilization of CNC lathes are one of the various machining services that we offer.

Benefits:

Maximum machining flexibility.

Best Used For:

A wide range of machining needs from production to job shop applications.

View Details -

Coating Rollers

We design and manufacture coating rollers, which are involved in the application process of coating substrates such as: paper, fabric, film, foil, and more.

Benefits:

Apply even coat weight due to uniformity.

Best Used For:

Coating Rollers

View Details -

Coating Thickness and Condition

Through our on-site and in-house capabilities we assess coating thickness and condition, which is an important measurement when understanding resurfacing or reconditioning needs.

Benefits:

Identify current life of coating layer.

Best Used For:

Wide range of applications.

View Details

Showing 1–30 of 190 results