-

Steering Rollers

Steering rollers are used to steer coils and webs.

Benefits:

Rollers are ozone and abrasion resistant, and will not degrade from oils or corrosive materials.

Best Used For:

Steering Rollers

View Details -

Storage Equipment/Tanks

Storage equipment, like tanks, are used to store manufacturing material.

Benefits:

Offer a variety of durable non-stick and wear-resistant coatings for tank interiors.

Best Used For:

A wide range of industries and applications

View Details -

Straightening Roll Bodies

By inspection and measurement of the size and wall thickness and the severity of the bend, the roller’s body can be straightened within original specifications.

Benefits:

Reduce costs in repair or replacement situations.

Best Used For:

Core Repair

View Details -

Stretch Rollers

Stretch rolls are also known as spreader rolls and used in a wide variety of web processing machines.

Benefits:

Increase machine speeds.

Best Used For:

Designd to remove wrinkles from the substrate.

View Details -

Strong Backs for Doctor Blades

Doctor blades frequently experience contamination build-up.

Benefits:

Coatings are high release and wear-resistant to minimize build-up thus reducing sheet breaks.

Best Used For:

A wdie range of converting industries.

View Details -

Structural Steel

On-site coating solutions can be applied to structural steel to reduction corrosion and wear. Thermal Spray Aluminum (TSA) is a common coating process utilized.

Benefits:

Corrosion control and prevention.

Best Used For:

Steel structures and components.

View Details -

Sulfur Condenser Head

Sulfur condensers require corrosion-resistant linings because of the environment they are used in to reclaim sulfur from hydrogen sulfide in raw natural gas.

Benefits:

Extend service life.

Best Used For:

A wide range of industries and applications

View Details -

Super Heat Assembly

Super heat assemblies are used in a variety of steam based applications.

Benefits:

Due to high heat inputs, coatings are used to protect areas from excessive wear.

Best Used For:

A wide range of industries and applications

View Details -

Support Rollers for Electrically Charged Processes

Support rollers for electrically charged processes require electrical insulation.

Benefits:

Offer various coverings and coatings to be tailored to your application.

Best Used For:

Support Rollers for Electrically Charged Processes

View Details -

Surface Energy (Wettability) Testing

Surface energy (wettability) testing is one of the services we offer as part of our physical property testing.

Benefits:

Evaluate surface characteristics.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Surface Finish (Roughness) Testing

Surface finish (roughness) testing is one of the services we offer as part of our physical property testing.

Benefits:

Determine surface roughness (RA)

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Surface Traction

By using a high traction coating, slippage is eliminated resulting in a more consistent performance resulting in improved machine traction.

Benefits:

Ensure tight starts, eliminate slippage and wrinkles, and improve web tracking and tension control.

Best Used For:

Traction control in on web processing machines.

View Details -

-

Tables

Tables, like the ones found within coal-fired broilers, are able to be coated with our corrosion-resistant technology to protect from corrosion and other wear.

Benefits:

Corrosion-resistant technology to protect from corrosion and other wear.

Best Used For:

Used in the power and coal industry.

View Details -

Take Up Rollers

We provide wear-resistant, easily cleaned, coatings for take up rollers, which are similar to s-wrap rollers because they guide webs around a specific shape.

Benefits:

Increase machine speeds and quality.

Best Used For:

Take Up Rollers

View Details -

Tank Coatings

We manufacture and apply both electrically conductive and electrically insulated tank coatings.

Benefits:

Reduce corrosion, contamination and product build up.

Best Used For:

Tank coatings in a wide variety of industries.

View Details -

Tanks

Our tank coatings and thermal spray metallic solutions are low traction, wear-resistant, and easily cleaned.

Benefits:

Coatings can be applied on-site at your facility.

Best Used For:

A wide range of industries and applications

View Details -

Temperature Profile

A service we provide that records and inteprets the temperatures of a roll while in use.

Benefits:

Determine temperature levels in process.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Tensiometer Rollers

Tensiometer rollers are used in the steel industry and it is important to utilize the correct materials of construction to ensure peformance and long lasting life.

Benefits:

Longer service life.

Best Used For:

Tensiometer Rollers

View Details -

Tensioner Rods

Tensioner Rods

Best Used For:

A wide range of industries and applications

View Details -

Thermal Conductive

Thermally Conductive and Semi-Conductive Coatings do not significantly impede the flow of heat in or out of the substrate that is coated.

Benefits:

Provide other unique surface properties such as cut and abrasion resistance or release.

Best Used For:

These are used in applications where rapid heat transfer is important, such as heated and chilled rollers.

View Details -

Thermal Conductivity Testing

Thermal conductivity testing is one of the services we offer as part of our physical property testing.

Benefits:

Determin thermal conductivity.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Thermal Insulating

Thermal Insulating coatings prevent the substrate from giving up internal heat or absorbing heat from an external source.

Benefits:

Temperature uniformity and efficient heat transfer.

Best Used For:

A wide variety of applications.

View Details -

Thermal Spray

Method of applying materials onto a base material by heating particles, creating a semi-molten state. Particles then propelled by high velocity onto a substrate and adhere via a mechanical bond.

Benefits:

This technique is considered the "cold method of welding", where high temperatures can be achieved in the heated pocket, while the temperature of the part itself usually remains under 200°F.

Best Used For:

Utilized to apply metal and ceramic based coatings.

View Details -

Thermal Spray Aluminum (TSA)

Thermal spray aluminum (TSA) coating are used to protect the exterior of process vessels, tanks, and other equipment in onshore and offshore oil and gas rigs, processing plants.

Benefits:

Corrosion protection.

Best Used For:

Process vessels, tanks, equipment in onshore and offshore oil and gas rigs, paper, petrochemical, refining, and process industries. Decorative railing, beams, bridge and structural steel components.

View Details -

Thermal Transfer Rollers

We manufacture a variety of precision thermal transfer rollers with a variety of surface finish options designed to withstand their thermal environments.

Benefits:

Custom designed solutions for specific process conditions.

Best Used For:

Thermal Transfer Rollers

View Details -

TIG Welding

TIG welding is one of the various technologies we are capable of using during cladding, welding, and fabrication.

Benefits:

Wide variety of benefits.

Best Used For:

A wide variety of applications.

View Details -

Top & Bottom Bead Mold

Top & Bottom Bead Mold

Best Used For:

A wide range of industries and applications

View Details -

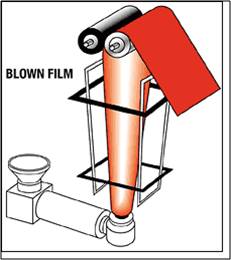

Tower Nip Rollers

Tower nip rollers are made from elastomeric compounds, both natural and synthetic.

Benefits:

Provide various tight tolerance, wear-resistant, seamless nip rollers.

Best Used For:

Tower Nip Rollers

View Details -

Tower Rollers

Tower rollers are made from stainless steel and can be high-polished or custom grooved.

Benefits:

Provide various durable, tight tolerance, seamless tower rollers.

Best Used For:

Tower Rollers

View Details

Showing 361–390 of 435 results