-

PLASMA 43000 SERIES

Coatings from our PLASMA 43000 series are a specialty polymer and offer a smooth coating with enhanced release characteristics and superior resistance to permeation.

Benefits:

Smooth coating with enhanced release characteristics and superior resistance to permeation.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 45000 SERIES

Coatings from our PLASMA 45000 series represent our line of Electroless Nickel offerings.

Benefits:

Electroless Nickel coatings provide wear resistance, low COF, and corrosion protection. With PTFE to some of the electroless nickel systems: lower cof, higher release, and increased hardness can be obtained.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 500 SERIES

Coatings from our PLASMA 500 series are baked polymers that offers superior chemical and corrosion resistance.

Benefits:

Smoothness and thickness will vary dependent on the environment they're exposed to and they have a max temperature of 280°F.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 600 SERIES

Coatings from our PLASMA 600 series are ceramic, and provide excellent wear and corrosion-resistance.

Benefits:

Excellent wear and corrosion-resistance.

Best Used For:

A wide variety of applications requiring corrosion and wear resistance.

View Details -

PLASMA 700 SERIES

Coatings from our PLASMA 700 series offer excellent release of adhesives and rubber.

Benefits:

Provides high traction, excellent web tracking and moderate wear resistance.

Best Used For:

A wide variety of applications requiring traction and wear resistance.

View Details -

PLASMA 800 SERIES

The 800N series is a smooth, slick, tough coating which derives its durability from a combination of hardness, resiliency, and low permeability.

Benefits:

The 800LI series is a traction coating offers a high coefficient of friction without the use of silicone.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 900 SERIES

Coatings from our PLASMA 900 series have excellent release of adhesives and rubber, and demonstrate high traction, web tracking, and abuse resistance with an ambient cure.

Benefits:

Excellent release of adhesives and rubber, and demonstrate high traction, web tracking, and abuse resistance with an ambient cure. They are applicable on-site at your facility.

Best Used For:

A wide variety of on-site applications.

View Details -

Plasma Dragon Elite

The Draon Elite coating is a work horse coating with excellent release properties.

Benefits:

The Draon Elite coating is a work horse coating with excellent release properties.

Best Used For:

A wide variety of applications.

View Details -

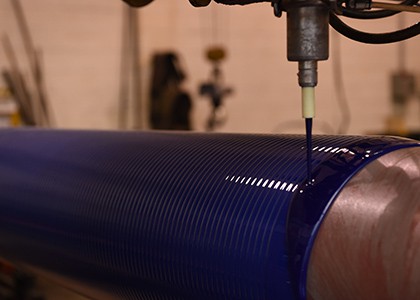

Plasma Spray

In this process we use various gasses that are ignited by an electric arc. Temperatures can rise up to 30,000° F while the part temperature remains at less than 200°F.

Benefits:

Particle velocity is greater than in the other four systems. One of the benefits of using this system is the high heat, which can process materials with high melting points (including ceramics).

Best Used For:

Utilized to apply metal and ceramic based coatings.

View Details -

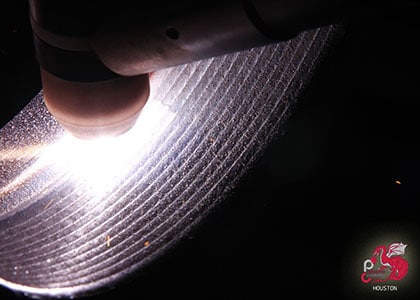

Plasma Transferred Arc

We manufacture and utlize plasma transferred arc welding or cladding systems to provide wear and corrosion resistant coatings or claddings.

Benefits:

Provide a protective wear layer or rebuild parts back to original dimensional integrity.

Best Used For:

This technology is used to rebuild surfaces back to original dimensional integrity.

View Details -

Plating

Plating often involves two process materials and/or steps where the first material bonds to the base material and serves as the primer for finish plating.

Benefits:

A wide range of surface property enhancements.

Best Used For:

A wide variety of applications.

View Details -

Powder Coat

The powder coat process is used in many of our polmyer coating processes.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

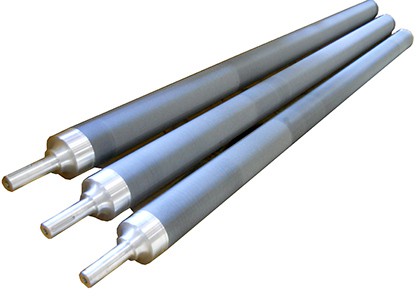

Press Rollers

Press rolls are used in a wide variety of industries and applications.

Benefits:

These rollers are made out of many different substrates and coverings or coatings.

Best Used For:

Press Rollers

View Details -

Pressure Rollers

Pressure rolls are used in the corrugating industry and are typically chrome or hard faced rolls. Often times these rolls are also crowned for deflection.

Benefits:

Increase machine speeds and longer service life.

Best Used For:

Pressure Rollers

View Details -

Pull Rollers

Pull rollers are driven nip rollers that pull subtrants.

Benefits:

Rollers are ozone and abrasion resistant, and will not degrade from oils or corrosive materials.

Best Used For:

Pull Rollers

View Details -

Quality Assurance

Our quality department and process is ISO 9001 compliant and in some plants certified.

Benefits:

We follow a rigid PPAP process for new product design and on-boarding.

Best Used For:

Quality program management.

View Details -

Re-Grinding

Re-grinding is often done to remove existing plating, for example chrome plating, from converting rollers and industrial parts due to scratches, dents, and existing worn areas.

Benefits:

Remove existing material due to scratches, dents, and existing worn areas.

Best Used For:

A wide variety of applications.

View Details -

Re-Journaling

Re-journaling rollers is often done as a repair on an existing rollers. The existing journal is removed and a new journal is machined and welded into place.

Benefits:

Re-store to original and critical dimensions; thus reducing replacement costs.

Best Used For:

Journal Repair

View Details -

Re-shelling

Re-shelling is considered if the outer shell is damaged or has experienced internal corrosion, and it’s possible to cut off the other shell and re-shell.

Benefits:

Reduce costs in repair or replacement situations.

Best Used For:

Heat Transfer and Chill Rolls

View Details -

Reel Drums

We are able to coat reel drums with release, traction, and wear-resistant coatings for their use within the paper industry.

Benefits:

Imrpoves traction, release and wear properties resulting in better parent roll integrity.

Best Used For:

Reel Drums

View Details -

Reel Drums Coatings

Our reel drum coatings are wear-resistant with high traction to provide a uniform wrap of your product. Coatings can be applied on-site at your facility.

Benefits:

Wear resistant and traction coatings that can be applied on-site.

Best Used For:

Reel Drums Coatings

View Details -

Release & Cleanability

Certified DuPont Licensed Industrial Applicator (DLA), user of Whitford coatings, and we blend our own, resulting in leading the industry in release coating services for a variety of industries.

Benefits:

Non-stick and release properties on surfaces.

Best Used For:

Our coatings reduce the clean up and build-up of such materials as starches, paints, adhesives, latex, rubber, food, paper, ice, sugar, resins, tapes, inks.

View Details -

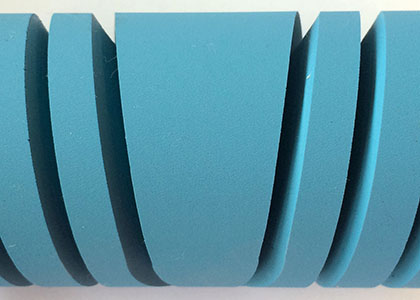

Reverse Tapers (concave crowns)

Spreader rollers’ grooving can take many forms including: herringbone pattern, chevron groove pattern, and reverse tapers (also known as concave crowns).

Benefits:

Custom finish solutions.

Best Used For:

A wide variety of applications.

View Details -

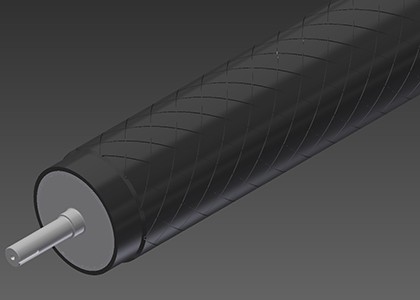

Rollers Crowning

Roll crowning is intended to ensure proper web alignment and helps minimize the effects of deflection.

Benefits:

Minimize the effects of deflection.

Best Used For:

A wide variety of applications.

View Details -

Rollers Grooving

Roller grooving is available in herringbone, chevron, and spiral groove patterns.

Benefits:

Improved web handling; wrinkle release

Best Used For:

A wide variety of applications.

View Details -

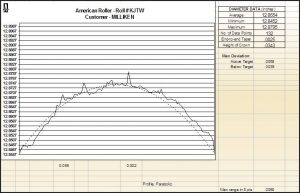

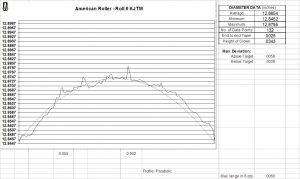

Rollers Run Out

Roller run out is a measurement of the roller’s surface roundness compared to the bearing surface.

Benefits:

Determine roller uniformity

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Rotary Die

Rotary die rollers are used in crush-cutting material between a cylindrical die and anvil.

Benefits:

Coated for clean ability, wear-resistance, and more.

Best Used For:

A wide range of industries and applications

View Details -

S-Wrap Rollers

We offer coating technologies for s-wrap rollers, which are critical fixed-position control points when a web is guided around the rollers in an “s”-shape.

Benefits:

Increase machine speeds and quality.

Best Used For:

S-Wrap Rollers

View Details -

Seal Bars

Seal bars are most often coated with thermally conductive low-friction coatings that offer great clean ability and good temperature profile performance.

Benefits:

Extend service life and prevent product build up.

Best Used For:

A wide range of industries and applications

View Details -

Sealing Rollers

We offer a wide variety of covering and coatings for sealing rollers including: non-stick, corrosion-resistant, and high temperature-resistant solutions.

Benefits:

Non-stick, corrosion-resistant, and high temperature-resistant surface properaties.

Best Used For:

Sealing Rollers

View Details

Showing 211–240 of 287 results