-

Expandable sleeves

Expandable sleeves are used in various markets.

Benefits:

Sleeves have elastomeric coverings, solving issues with increased cooling and reduced static build-up.

Best Used For:

A wide variety of industries.

View Details -

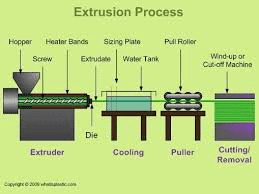

Extrusion Equipment

Extrusion equipment is coated with abrasion-resistant and high-release coatings to address issues faced in the various industries this equipment is used in.

Benefits:

Abrasion-resistant and high-release coatings

Best Used For:

A wide variety of industries.

View Details -

Fabric Cutter Tables

We offer coating solutions for fabric cutter tables to provide easier clean ability and low friction when in contact with green rubber during your application.

Benefits:

Easier clean ability and low friction

Best Used For:

Tire and rubber manufacturing process

View Details -

Fan Blades

Gas mixed with fine particles can cause wear or unbalance when they stick to fan blades.

Benefits:

Apply protective coatings to prevent wear and improve self-cleaning.

Best Used For:

A wide variety of industries.

View Details -

Fingers

Fingers are flat stock that separates product from each other.

Benefits:

Apply low-friction wear-resistant coatings to slow down ink build-up and make cleaning easier.

Best Used For:

Used in the printing industry.

View Details -

Fluidizing Beds

We offer coating solutions that provide wear-resistant, low-friction, non-stick surfaces for fluidizing beds, which deal with difficult to handle materials.

Benefits:

Wear-resistant, low-friction, non-stick surfaces with difficult to handle materials.

Best Used For:

We offer coating solutions that provide wear-resistant, low-friction, non-stick surfaces for fluidizing beds, which deal with difficult to handle materials.

View Details -

Folding Horn

We coat folding horns with durable, wear-resistant, low-friction coatings which increases production throughput and less rejects during the converting process.

Benefits:

Increases production throughput and less rejects during the converting process.

Best Used For:

A wide variety of high temperature applications.

View Details -

Folding Rails

We coat folding rails with durable, wear-resistant, low-friction coatings which increases production throughput and less rejects during the converting process.

Benefits:

Increases production throughput and less rejects during the converting process.

Best Used For:

A wide range of converting processess.

View Details -

Glue Applicator

Coating glue applicators allows for easier cleanability during normal maintenance.

Benefits:

Easier cleanability

Best Used For:

A wide range of converting processess.

View Details -

Grinders

Grinder rollers are used in ore crushing machines and are tungsten carbide coated for durability.

Benefits:

Wear-resistant coatings for your application.

Best Used For:

Used in the mining and metals industry.

View Details -

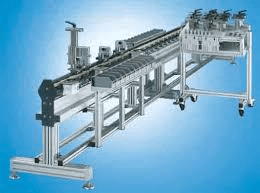

Guide Rails

Guide rails are used to control web handling for manufacturing and converting processes.

Benefits:

Coat guide rails to assist in the function of the overall unit.

Best Used For:

A wide range of converting processess.

View Details -

Heat Bars

Heat bars are used in various sealing operations.

Benefits:

Apply non-stick coatings to heat bars to provide more precise, repetitive sealing and easier cleanability.

Best Used For:

A wide range of industries and applications

View Details -

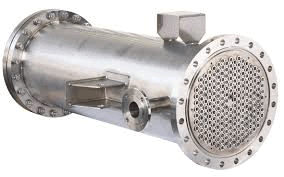

Heat Exchanger

Heat exchangers are used in corrosive and abrasive environments.

Benefits:

Coat them with a wide range of alloys that address the issues of corrosion and abrasion.

Best Used For:

A wide range of industries and applications

View Details -

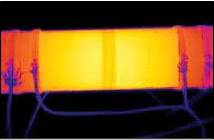

Heated Piping

Heated piping is coated to maintain uniform temperature across the face of a pipe.

Benefits:

Apply patended SmartHeat technology to keep temperatures uniform.

Best Used For:

A wide range of industries and applications

View Details -

High Pressure Separator Vessels

High pressure separator vessels commonly have issues with corrosion and fouling.

Benefits:

Engineer and apply coatings that can address corrosion and fouling.

Best Used For:

A wide range of industries and applications

View Details -

Holding Tanks

We engineer and apply a variety of low friction, high release, and easily cleaned coatings for holding tank interiors.

Benefits:

Extend service life.

Best Used For:

A wide range of industries and applications

View Details -

Hot Melt

We provide release coatings on a number of parts that are exposed to hot-melt adhesives where “no-stick” and release is needed to improve productivity and clean-up.

Benefits:

No-stick and release is needed to improve productivity and clean-up.

Best Used For:

A wide range of converting processess.

View Details -

Hot Melt Pans

Hot melt pans are used to collect excess hot melt adhesive during application.

Benefits:

Offer various coatings designed for wear-resistance and easier cleanability.

Best Used For:

A wide range of converting processess.

View Details -

Hydraulic Pistons

Hydraulic pistons often face abrasion and galling.

Benefits:

Provide turnkey components and coatings to reduce wear ability and extend service lives of the pistons.

Best Used For:

A wide range of industries and applications

View Details -

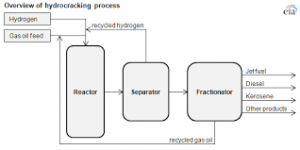

Hydro Cracker Reactors

Hydro cracker reactors vessels commonly have issues with corrosion and fouling.

Benefits:

Engineer and apply coatings that can address corrosion and fouling.

Best Used For:

A wide range of industries and applications

View Details -

Ink Pans

Ink pans are used to contain ink that is to be applied onto substrates.

Benefits:

Offer various coatings designed to significantly ease the cleanability of the pans.

Best Used For:

Used in the printing industry.

View Details -

Ink Tanks

Ink tanks are used to contain ink that is to be applied onto substrates.

Benefits:

Offer various coatings designed to significantly ease the cleanability of the tanks.

Best Used For:

Used in the printing industry.

View Details -

-

Machine Frame

We deisgn, engineer and apply coatings to machine frames for wear and corrosion resistance to extend their life spans.

Benefits:

Service is provided on-site.

Best Used For:

A wide range of industries and applications

View Details -

Mills

We manufacture wear-resistant, non-stick corrosion-resistant coatings to improve the efficiency and down time of mills.

Benefits:

Improve the efficiency and down time of mills.

Best Used For:

A wide range of industries and applications

View Details -

Mixing Equipment

Mixing equipment is used to blend a wide range of materials.

Benefits:

Apply wear-resistant and non-stick coatings to the mixer surfaces to enhance performance.

Best Used For:

A wide range of industries and applications

View Details -

Mixing Vessels/Paddles

Mixing vessels/paddles are used to blend a wide range of materials.

Benefits:

Apply wear-resistant and non-stick coatings to the mixer surfaces to enhance performance.

Best Used For:

A wide range of industries and applications

View Details -

Molds

We manufacture durable, wear-resistant, release coatings for molds, and various other molding equipment, to resist and protect against product build-up.

Benefits:

Resist and protect against product build-up.

Best Used For:

A wide range of industries and applications

View Details -

Nozzles

Nozzles can be heated in order to maintain a consistent temperature throughout the nozzle.

Benefits:

Wired non-conductive coatings.

Best Used For:

A wide range of industries and applications

View Details

Showing 31–60 of 107 results