-

5-Axis Machining

We offer 5-axis machining of parts. This service is when our CNC machine is needed to approach the part from multiple directions.

Benefits:

Maximum machining flexibility.

Best Used For:

A wide range of machining needs from production to job shop applications.

View Details -

Acid Flushing

Acid flushing breaks down and flushes out the internal corrosion deposits and blockages in heat transfer rollers to improve flowrates and improve thermal conductivity.

Benefits:

Improves efficiencies in heat transfer rates.

Best Used For:

Heat Transfer and Chill Rolls

View Details -

Airless Spray

Airless spray is one of our application techniques for applying several different type of coatings.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

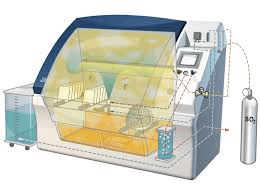

Analytical Property Testing

Specific testing methods that include; Ash and Soxhlet Extraction Analysis, FT-IR Analysis by Diamond ATR, and FT-IR Spectrophotometric Analysis.

Benefits:

Identify root cause problems and limitiations from current performance.

Best Used For:

This is used to understand material composition and improve upon performance characteristics.

View Details -

Anodizing

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish.

Benefits:

Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

Best Used For:

We provide anodizing to a wide variety of parts and is one of the various services that we offer.

View Details -

Anvil Rollers

Anvil rollers, also known as slitter rollers, are hardened rollers on which a circular cutter rides in order to part, slit or perforate the web.

Benefits:

Some slitter rollers are multi-grooved over which a razor or razors are mounted to slit the web.

Best Used For:

Anvil rollers are used for slitting (separating) applications.

View Details -

Balancing

Two plane and 3 plane balancing is a common request. Detailed balance reports are provided post-balancing, ensuring that roller and parts perform in an optimal manner.

Benefits:

This is increasingly important in today's high running machine speeds.

Best Used For:

Roll and machine balance.

View Details -

Box Repair

We offer roller and crating repairs on storage and transport boxes, which are repaired and refurbished with our in-house capabilities.

Benefits:

Re-store transportation containers reducing cost.

Best Used For:

Box Repair

View Details -

Broaching

Broaching is a machining process that uses a toothed tool to remove material. Typical workpieces include small to medium-sized castings, forgings, screw machine parts, and stampings.

Benefits:

Maximum machining flexibility.

Best Used For:

Broaching is used when precision machining is required, especially for odd shapes. Commonly machined surfaces include circular and non-circular holes, splines, keyways, and flat surfaces.

View Details -

Building-Up & Re-machining Journals

Building up (welding) and re-machining is usually done if a journal is worn, damaged, or simply bent- ultimately impacting the performance of web processing.

Benefits:

Re-store journals to original and critical dimensions; thus reducing replacement costs.

Best Used For:

Journal Repair

View Details -

Calender Rollers

Calender rollers, which are usually configured in pairs, are used to gauge a web to a predetermined thickness by running the web through a controlled gap.

Benefits:

Calender rollers are series of hard pressure rollers that are used on-line or off-line to form or smooth a sheet of material like paper or plastic film.

Best Used For:

Calendar Rollers

View Details -

Centerless Grinding

Centerless grinding is process that uses abrasive cutting to remove material. This differs from centered grinding operations in that no spindle or fixture is used to locate and secure the workpiece.

Benefits:

Workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece.

Best Used For:

A wide variety of applications.

View Details -

Chemical Resistance Property Testing

These tests are conducted to determine chemical resistance characteristics of a covering, coating or finished part.

Benefits:

(1) Customer Media Immersion Testing (2) Volume, Weight and Hardness Change Data (3) Corrosion Resistance Testing (4) Solvent Wipe Testing

Best Used For:

Wide range of problem solving applications around corrosion protection.

View Details -

Chevron or Herringbone Grooving

Spreader rollers grooving can take many forms including: herringbone pattern, chevron groove pattern, reverse taper configuration, and grooved rubber covers.

Benefits:

Improved web handling; wrinkle release

Best Used For:

Bowed roll and stretch roll applications.

View Details -

Chill Roll Chrome Repair

Chill roller chrome repair includes: re-chroming, acid flushing, chrome, and recovering. See the newly released CHROME+ solution which extends life beyond typical chrome repair processes.

Benefits:

Chill roller chrome repair helps reduce the need for overall roller repairs and improves heat or cooling efficiency transfer rates.

Best Used For:

Heat Transfer and Chill Rolls

View Details -

Chrome Plus +

Chrome Plus is a environmentally friendly carbide coating replacement for Chrome. With equivalent price, performance, surface finish and thermal transfer properties.

Benefits:

Green replacement for Chrome. A scratch resistant and repair capable coating for use in a wide variety of applications.

Best Used For:

Heat transfer and chill rolls and other metals surfaces.

View Details -

CNC Lathes

The utilization of CNC lathes are one of the various machining services that we offer.

Benefits:

Maximum machining flexibility.

Best Used For:

A wide range of machining needs from production to job shop applications.

View Details -

Coating Thickness and Condition

Through our on-site and in-house capabilities we assess coating thickness and condition, which is an important measurement when understanding resurfacing or reconditioning needs.

Benefits:

Identify current life of coating layer.

Best Used For:

Wide range of applications.

View Details -

Combustion Wire Metallizing

In this process, various metal wire is fed into an oxygen-acetylene gas mixture. It is then in a molten state and sprayed onto the part being processed.

Benefits:

This most basic of coating techniques is limited by maximum temperature attainable and the universe of materials that can be set.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Compression Load Deflection Testing

Compression Load Deflection Testing is one of the services we offer as part of our physical property tests.

Benefits:

This is useful in determing how a rubber covering will perform in a process condition.

Best Used For:

It is a nondestructive method for determining relationship between compressive load and deflection under load for vulcanized rubber. (ASTM D-575).

View Details -

Core Repair

Rebuilding cores is a routine service we perform. We also possess the capability to provide metrics on frequency of core repair so as to manage spends in the most cost effective way.

Benefits:

We can provide FEA analysis to help solve issues with production.

Best Used For:

Core Repair

View Details -

Corrosion Protection

We have a wide range of coating options to help address corrosion. Pptions include the application of thermally sprayed metals and polymers or a combination of the two technologies.

Benefits:

In many instances, our coatings can address the corrosive problem while providing secondary benefits such as release or improved surface hardness promoting erosion resistance.

Best Used For:

A wide range of corrosion protection applications.

View Details -

Corrosion Resistance Testing

Corrosion Resistance Testing is one of the services we offer as part of our Chemical Resistance Property Testing.

Benefits:

Often this is an important test in determining the correct material and application process for coating or covering your parts in the application targeted.

Best Used For:

Wide range of applications.

View Details -

Dancer Rollers

Dancer rollers are lightweight dead or live shaft idlers that sense changes in web tension. The lighter the weight, the more sensitive the rollers will be.

Benefits:

Assists in tention control on a web processing machine improving web tracking and increasing machine speeds.

Best Used For:

Controlling tension on a web.

View Details -

Dimension Checks for Journal and Body

Dimension checks for journal and bodies are reviews of a roller journal and body used to verify dimensions and advise on repairs or reconditioning as needed.

Benefits:

Re-store rollers to original state.

Best Used For:

Journal and Core Body Repair

View Details -

Drive Rollers

Drive rollers drive opposing nip rollers, allowing substrates to move through the web’s path.

Benefits:

Available in alloy steel, carbon steel, and stainless steel.

Best Used For:

Drive Rollers

View Details -

Dryer Drums

We coat dryer drums with durable, speciality formulated non-stick surfaces.

Benefits:

Allows dryer drums to run at higher speeds, with less sheet breaks and contamination or build up issues.

Best Used For:

Dryer Drums

View Details -

Durometer Measure

Durometer is the international standard used for measurement of rubber hardness in the roller industry and also refers to the instrument itself.

Benefits:

Measure and control roller hardness.

Best Used For:

This is a standard specification we define some products and servics with, providing documentation to our customers.

View Details -

Dynamic Abrasion Testing

Dynamic abrasion testing is one of the services we offer as part of our dynamic property testing.

Benefits:

This test is used in the pursuit of designing longer-lasting coverings and coatings.

Best Used For:

This test is used to determine resistance to wear of a particular coating or covering.

View Details -

Dynamic Property Testing

These tests are utilized to understand a coating or coverings response to pressure, heat and wear.

Benefits:

The tests include: Static Release Dynamic Abrasion Testing Pilot Testing Hysteresis (Heat Buildup) Testing

Best Used For:

Wide range of problem solving applications and analysis.

View Details

Showing 1–30 of 168 results