-

Release & Cleanability

Certified DuPont Licensed Industrial Applicator (DLA), user of Whitford coatings, and we blend our own, resulting in leading the industry in release coating services for a variety of industries.

Benefits:

Non-stick and release properties on surfaces.

Best Used For:

Our coatings reduce the clean up and build-up of such materials as starches, paints, adhesives, latex, rubber, food, paper, ice, sugar, resins, tapes, inks.

View Details -

Reverse Tapers (concave crowns)

Spreader rollers’ grooving can take many forms including: herringbone pattern, chevron groove pattern, and reverse tapers (also known as concave crowns).

Benefits:

Custom finish solutions.

Best Used For:

A wide variety of applications.

View Details -

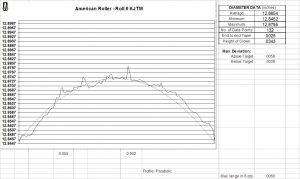

Rollers Crowning

Roll crowning is intended to ensure proper web alignment and helps minimize the effects of deflection.

Benefits:

Minimize the effects of deflection.

Best Used For:

A wide variety of applications.

View Details -

Rollers Grooving

Roller grooving is available in herringbone, chevron, and spiral groove patterns.

Benefits:

Improved web handling; wrinkle release

Best Used For:

A wide variety of applications.

View Details -

Rollers Run Out

Roller run out is a measurement of the roller’s surface roundness compared to the bearing surface.

Benefits:

Determine roller uniformity

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Rotary Die

Rotary die rollers are used in crush-cutting material between a cylindrical die and anvil.

Benefits:

Coated for clean ability, wear-resistance, and more.

Best Used For:

A wide range of industries and applications

View Details -

Seal Bars

Seal bars are most often coated with thermally conductive low-friction coatings that offer great clean ability and good temperature profile performance.

Benefits:

Extend service life and prevent product build up.

Best Used For:

A wide range of industries and applications

View Details -

Sealing Rollers

We offer a wide variety of covering and coatings for sealing rollers including: non-stick, corrosion-resistant, and high temperature-resistant solutions.

Benefits:

Non-stick, corrosion-resistant, and high temperature-resistant surface properaties.

Best Used For:

Sealing Rollers

View Details -

Shaft Repairs

Wear and abarasion resistant coatings can be applied to shafts. Shafts can also be rebuilt or “remanufactured” to original dimensions using cladding technologies.

Benefits:

Reduce costs in repair or replacement situations.

Best Used For:

Shaft Repair

View Details -

Side Face and Journals

Side faces and journals on rollers need increased protection,reburbishment and repair.

Benefits:

Extend service life.

Best Used For:

A wide range of industries and applications

View Details -

-

-

Sleeving & Re-boring

Sleeving and re-boring are often done on journals where a critical journal diameter is worn. A sleeve is machined and put in place within the roller’s bearing.

Benefits:

Reduce costs in repair or replacement situations.

Best Used For:

Journal Repair

View Details -

Solvent Wipe Testing

Solvent wipe testing is one of the services we offer as part of our chemical resistance property testing.

Benefits:

Chemical Resistance Property Testing.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Spider Wheels

Spider wheels are used to separate product.

Benefits:

Wheel coatings are low-friction, wear-resistant, easily-cleaned, and reduce ink built-up to improve application.

Best Used For:

Used in the printing industry.

View Details -

Spiral Grooving for Air Entrapment Removal

Spreader rollers’ grooving can take many forms including: spiral grooving, chevron groove pattern, reverse taper configuration, and grooved rubber covers.

Benefits:

Improved web handling; wrinkle release

Best Used For:

A wide variety of applications.

View Details -

Splicing Bump Rollers

Splicing bump rollers are used in manufacturing within the paper, film, and foil industries. Their purpose is joining webs that are expiring to new webs.

Benefits:

Increase machine speeds and reduct sheet breaks.

Best Used For:

Purpose is joining webs that are expiring to new webs.

View Details -

Static Release

Static release testing is one of the services we offer as part of our dynamic property testing.

Benefits:

Determine static release properties.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Steam Hoods

Steam hoods are used where hot water steam is collected.

Benefits:

Offer FDA compliant non-permeable Plasma Coatings that withstand high temperatures to prevent corrosion.

Best Used For:

A wide range of industries and applications

View Details -

Straightening Roll Bodies

By inspection and measurement of the size and wall thickness and the severity of the bend, the roller’s body can be straightened within original specifications.

Benefits:

Reduce costs in repair or replacement situations.

Best Used For:

Core Repair

View Details -

Stretch Rollers

Stretch rolls are also known as spreader rolls and used in a wide variety of web processing machines.

Benefits:

Increase machine speeds.

Best Used For:

Designd to remove wrinkles from the substrate.

View Details -

Support Rollers for Electrically Charged Processes

Support rollers for electrically charged processes require electrical insulation.

Benefits:

Offer various coverings and coatings to be tailored to your application.

Best Used For:

Support Rollers for Electrically Charged Processes

View Details -

Surface Energy (Wettability) Testing

Surface energy (wettability) testing is one of the services we offer as part of our physical property testing.

Benefits:

Evaluate surface characteristics.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Surface Finish (Roughness) Testing

Surface finish (roughness) testing is one of the services we offer as part of our physical property testing.

Benefits:

Determine surface roughness (RA)

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Surface Traction

By using a high traction coating, slippage is eliminated resulting in a more consistent performance resulting in improved machine traction.

Benefits:

Ensure tight starts, eliminate slippage and wrinkles, and improve web tracking and tension control.

Best Used For:

Traction control in on web processing machines.

View Details -

Tank Coatings

We manufacture and apply both electrically conductive and electrically insulated tank coatings.

Benefits:

Reduce corrosion, contamination and product build up.

Best Used For:

Tank coatings in a wide variety of industries.

View Details -

Temperature Profile

A service we provide that records and inteprets the temperatures of a roll while in use.

Benefits:

Determine temperature levels in process.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Thermal Conductive

Thermally Conductive and Semi-Conductive Coatings do not significantly impede the flow of heat in or out of the substrate that is coated.

Benefits:

Provide other unique surface properties such as cut and abrasion resistance or release.

Best Used For:

These are used in applications where rapid heat transfer is important, such as heated and chilled rollers.

View Details -

Thermal Conductivity Testing

Thermal conductivity testing is one of the services we offer as part of our physical property testing.

Benefits:

Determin thermal conductivity.

Best Used For:

Wide range of problem solving applications and analysis.

View Details

Showing 211–240 of 270 results