-

Nickel Plating

Electroless Nickel plating offers some advantages over chrome plating. It has a better resistance to corrosion with relatively thinner coatings than chrome.

Benefits:

Electroless Nickel plating in the as-plated condition has a hardness of approximately 50Rc. It can be heat treated by baking to a hardness of approximately 70Rc.

Best Used For:

Electroless Nickel plating can be applied to aluminum and steel.

View Details -

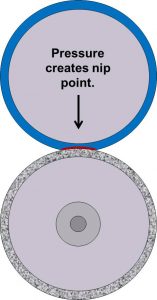

Nip Impressions

A nip impression is a measure of the uniformity of the pressure in a web processing nip. The pressure profile is sometimes referred to as a footprint.

Benefits:

This is useful in understanding how a machine is running or can run better. The company can provide a service in measuring the nip impression.

Best Used For:

Wide range of problem solving applications and analysis in the nip roll position of a web processing machine.

View Details -

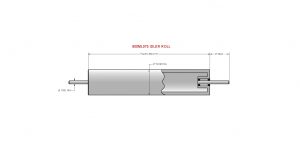

Nip Rollers

Our nip rollers are available in alloy steel, carbon steel, and stainless steel. Nip rollers are also known as pinch rollers and by various other names.

Benefits:

Proper selection affects product quality and line speeds.

Best Used For:

They are used to press two or more sheets together to form a laminated product.

View Details -

Non & Conductive Coatings

Conductive and non-conductive coatings are used promote or limit the flow of heat or electrical current into or away from the object that is coated.

Benefits:

Wide variety of metal, metal alloy, carbide matrix, ceramic, and polymer coatings available with these properties as well as combination coatings composed of thermal spray and polymer coatings.

Best Used For:

Conductive and non-conductive surface properties.

View Details -

Non Destructive Testing

Non destructive testing is analysis techniques used to evaluate the material of a roller or part without damaging it.

Benefits:

There is a wide variety of non-destructive tests utilized.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Nylon Rollers

Nylon rollers are extremely corrosion resistant and provide long service life in ink printing applications.

Benefits:

Replaces copper, steel or other smooth faced metering rollers used in directory or commercial printing where "high volume" ink flow is required.

Best Used For:

Ink printing applications.

View Details -

Overlaying Weld

Overlaying welds are utilized to help build up a roller’s body to a larger diameter, repair existing faces on rollers, or incorporate different properties.

Benefits:

Re-store to original and critical dimensions; thus reducing replacement costs.

Best Used For:

Core and Journal Repair

View Details -

Ozone Resistance Testing

Ozone resistance testing is one of the services we offer as part of our physical property testing.

Benefits:

Ozone resistance testing

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

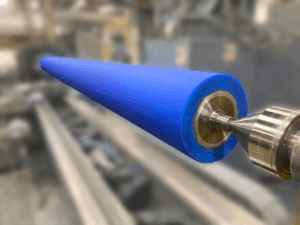

Pegasus

Pegasus rollers have foam polymer bases and offer superior compression and tear resistance. The patented, high release topcoat prevents picking and wrap-ups from adhesive contact.

Benefits:

Patented, high release topcoat prevents picking and wrap-ups from adhesive contact and seals the covering surface to prevent grease and other contaminants from penetrating the foam.

Best Used For:

Superior performer in an "no-crush" roll position weighing in at 70% less than rubber roll coverings. Less weight equates to better responsiveness, faster speed changes and less system drag.

View Details -

Pegasus II

The Pegasus II utilizes the same technology as the Pegasus I but features a more wear-resistant urethane outer covering.

Benefits:

These rollers are designed to compress and rebound back to its original size without generating heat.

Best Used For:

Lay on roll position.

View Details -

Pellex

Pellex offers specially formulated proprietary coverings and coatings that offer excellent abrasion resistance and overall force resistance which allows accurate delivery of the strands to the cutting unit, producing consistent, uniform pellets.

Benefits:

Specially formulated covering has outstanding abrasion resistance which allows for accurate delivery of the strands to the cutting unit, producing consistent, uniform pellets.

Best Used For:

Pelletizing equipment

View Details -

Physical Property Testing

We offer a wide rand of physical property testing which enables us to determin material composition and performance expectations in order to optimize application solutions.

Benefits:

Compression Load Deflection Testing, Hardness Testing, Tensile, Elongation and Tear, Ozone Resistance, Surface Energy (Wettability), Surface Finish (Roughness), Thermal Conductivity

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

PLASMA 100 SERIES

A chemical, rust-resistant, smooth, and slick polymer coating.

Benefits:

Moderate release characteristics, is very tough, and bonds excellently to various materials.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 15000 SERIES

Coatings from our PLASMA 15000 series offer a tough, low friction, dry lubricant with moderate release.

Benefits:

While maximum process temperature is documented at 700°F (LT series is 400°F), lower temperatures can be utilized if needed.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 200 HT SERIES

Coatings from our PLASMA 200 HT series are release coatings designed for high temperature applications.

Benefits:

They have a max service temperature of 500°F.

Best Used For:

A wide variety of high temperature applications.

View Details -

PLASMA 20000 SERIES

Coatings from our PLASMA 20000 series offer excellent corrosion resistance, release, and cleanability.

Benefits:

Combination of the material type and thickness results in excellent resistance to permeation.

Best Used For:

A wide variety of high temperature applications.

View Details -

PLASMA 21000 SERIES

Coatings from our PLASMA 21000 series are smooth release coatings that offer excellent corrosion resistance, low friction, and release of most materials including adhesives.

Benefits:

They are applicable on-site at your facility.

Best Used For:

A wide variety of applications.

View Details -

PLASMA 25000 SERIES

Coatings from our PLASMA 25000 series have an ambient cure coating which offers outstanding traction, web tracking, release, and toughness.

Benefits:

This series is our smoothest version of a traction/release coatings. This is the bake, cured version of the 10000 series.

Best Used For:

This is an ideal replacement for any traction alternative currently being used, such as tapes, cheese grate, sandpaper, and certain rubber coverings.

View Details

Showing 91–120 of 160 results