-

Layon Rollers

Layton rollers are manufactured and used to help reduce air entrapment when winding.

Benefits:

Higher speeds on web processing machines with tighter parent roll properaties.

Best Used For:

They are utilized within the paper, film, foil, and plastic industries.

View Details -

Lead-in Lead Out Rollers to dryer sections

Lead in and lead out rollers are also used to lead to dryer sections during manufacturing.

Benefits:

They are engineered with durable, non-stick, easily cleaned surfaces.

Best Used For:

Lead-in Lead Out Rollers to dryer sections

View Details -

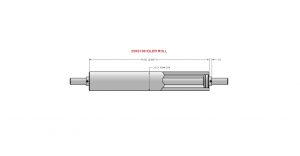

Lightweight Idler Rollers

Lightweight idler rollers are designed and used for delicate webs or where the lowest inertia is desired. Our rollers are manufactured with thin steel and/or aluminum or cabon fiber to reduce inertia.

Benefits:

Low inertia for high speed web processing machines.

Best Used For:

Lightweight idler

View Details -

LIMISTAT

Limistat is a series of electrically conductive rubber covered rollers designed to aid in dissipating static produced by webs.

Benefits:

Reduce static build-up in high speed web applications.

Best Used For:

Limistat functions best in high-speed webs that suffer from static electricity buildup.

View Details -

Liquid Dispersion

Liquid dispersion is a polymer coating process technique used in a wide variety of applications.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

Low Friction

Reduce the cleanup and buildup of such materials as starches, paints, adhesives, latex, rubber, food, paper, ice, sugar, resins, tapes, inks.

Benefits:

Extremely wear resistant and long lasting.

Best Used For:

Hard base onto your part and then impregnate one of our Low COF release agents into that coating.

View Details -

Machine Frame

We deisgn, engineer and apply coatings to machine frames for wear and corrosion resistance to extend their life spans.

Benefits:

Service is provided on-site.

Best Used For:

A wide range of industries and applications

View Details -

Machined Crowns

Roller crowning is intended to ensure proper web alignment and helps minimize the effects of deflection. Materials include several types of aluminum and steel.

Benefits:

Minimize the effects of deflection.

Best Used For:

A wide variety of applications.

View Details -

Mag. Particle Test

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) test for detecting surface and subsurface discontinuities in materials such as iron, nickel, cobalt, and some of their alloys.

Benefits:

Ensures product quality and uniformity.

Best Used For:

Often used as a quality verification process.

View Details -

Magna Flux Test

A magna flux test is a non-destructive testing (NDT) process for detecting surface, and subsurface, discontinuities in materials such as: iron, nickel, cobalt, and some of their alloys.

Benefits:

This process puts a magnetic field into the piece and the piece can be magnetized by direct or indirect magnetization.

Best Used For:

Often used as a quality verification process.

View Details -

-

Media Immersion Testing

Application media immersion testing is one of the services we offer as part of our Chemical Resistance Property Testing.

Benefits:

Chemical Resistance Property Testing.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

MIG Welding

Gas metal arc welding (GMAW), sometimes referred (MIG) welding or metal active gas (MAG) welding, is a welding process which heats the workpiece metal(s), causing them to melt and join.

Benefits:

A welding process in which an electric arc forms between a consumable wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to melt and join.

Best Used For:

A wide variety of welding applications.

View Details -

Mirror Finishing

Chrome plating is used where a “mirror” finish is needed.

Benefits:

Mirror finishing is a very smooth surface and can either decrease or increase web/roller friction.

Best Used For:

A wide variety of applications.

View Details

Showing 91–120 of 283 results