-

Combustion Wire Metallizing

In this process, various metal wire is fed into an oxygen-acetylene gas mixture. It is then in a molten state and sprayed onto the part being processed.

Benefits:

This most basic of coating techniques is limited by maximum temperature attainable and the universe of materials that can be set.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Compression Load Deflection Testing

Compression Load Deflection Testing is one of the services we offer as part of our physical property tests.

Benefits:

This is useful in determing how a rubber covering will perform in a process condition.

Best Used For:

It is a nondestructive method for determining relationship between compressive load and deflection under load for vulcanized rubber. (ASTM D-575).

View Details -

Core Repair

Rebuilding cores is a routine service we perform. We also possess the capability to provide metrics on frequency of core repair so as to manage spends in the most cost effective way.

Benefits:

We can provide FEA analysis to help solve issues with production.

Best Used For:

Core Repair

View Details -

Corrosion Protection

We have a wide range of coating options to help address corrosion. Pptions include the application of thermally sprayed metals and polymers or a combination of the two technologies.

Benefits:

In many instances, our coatings can address the corrosive problem while providing secondary benefits such as release or improved surface hardness promoting erosion resistance.

Best Used For:

A wide range of corrosion protection applications.

View Details -

Corrosion Resistance Testing

Corrosion Resistance Testing is one of the services we offer as part of our Chemical Resistance Property Testing.

Benefits:

Often this is an important test in determining the correct material and application process for coating or covering your parts in the application targeted.

Best Used For:

Wide range of applications.

View Details -

Dancer Rollers

Dancer rollers are lightweight dead or live shaft idlers that sense changes in web tension. The lighter the weight, the more sensitive the rollers will be.

Benefits:

Assists in tention control on a web processing machine improving web tracking and increasing machine speeds.

Best Used For:

Controlling tension on a web.

View Details -

Dead Plates

Dead plates are used to convey material.

Benefits:

Coating combinations to address issues likes: wear, friction, chemicals, sticking, and more.

Best Used For:

A wide variety of industries.

View Details -

Drive Rollers

Drive rollers drive opposing nip rollers, allowing substrates to move through the web’s path.

Benefits:

Available in alloy steel, carbon steel, and stainless steel.

Best Used For:

Drive Rollers

View Details -

DSB Sheet Rings

These components are used in the tire and rubber manufacturing process.

Benefits:

Rings are coated with release (non-stick) and wear resistance coatings.

Best Used For:

Tire and rubber manufacturing process

View Details -

Dynamic Abrasion Testing

Dynamic abrasion testing is one of the services we offer as part of our dynamic property testing.

Benefits:

This test is used in the pursuit of designing longer-lasting coverings and coatings.

Best Used For:

This test is used to determine resistance to wear of a particular coating or covering.

View Details -

Dynamic Property Testing

These tests are utilized to understand a coating or coverings response to pressure, heat and wear.

Benefits:

The tests include: Static Release Dynamic Abrasion Testing Pilot Testing Hysteresis (Heat Buildup) Testing

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Electric Arc

This process uses materials in wire form, but the heat source is the arcing of two electrically conductive wires. Material is melted and propelled on the part at a greater velocity than metallizing.

Benefits:

Higher temperatures allow for an increased source of base materials, faster rates of deposition, and improved bond and coating density.

Best Used For:

Utilized to apply metal based coatings.

View Details -

Electric Arc Furnace

We engineer and apply coating solutions that significantly increase the life of water-cooled electric arc furnace duct work.

Benefits:

Solutions are applicable on-site

Best Used For:

A wide variety of industries.

View Details -

Electrically Conductive

Our electrically conductive coatings can be applied to: anti-static idler rollers, anti-static tanks, bins, chutes, silo coatings, and web grounding rollers for charged webs.

Benefits:

Electrical conductivity.

Best Used For:

These coatings are also used in medical and electronic applications.

View Details -

Electrically Insulated

Our electrically insulated coatings can be applied to: bins, chutes, corona treater rollers, silo coatings, web insulated tanks, and support rollers for electrically charged processes.

Benefits:

Electrical insulation.

Best Used For:

They are also used in medical and electronic coating applications.

View Details -

Electrostatic

Through our electrostatic systems we are able to apply: fluorocarbons, fluoropolymers, silicones, epoxies, and Teflon® industrial coatings.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

Expandable sleeves

Expandable sleeves are used in various markets.

Benefits:

Sleeves have elastomeric coverings, solving issues with increased cooling and reduced static build-up.

Best Used For:

A wide variety of industries.

View Details -

Fabric Cutter Tables

We offer coating solutions for fabric cutter tables to provide easier clean ability and low friction when in contact with green rubber during your application.

Benefits:

Easier clean ability and low friction

Best Used For:

Tire and rubber manufacturing process

View Details -

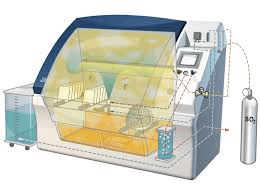

Fluidizing Beds

We offer coating solutions that provide wear-resistant, low-friction, non-stick surfaces for fluidizing beds, which deal with difficult to handle materials.

Benefits:

Wear-resistant, low-friction, non-stick surfaces with difficult to handle materials.

Best Used For:

We offer coating solutions that provide wear-resistant, low-friction, non-stick surfaces for fluidizing beds, which deal with difficult to handle materials.

View Details -

Foam Rollers

Foam rollers are manufactured from cellular material and used in a wide variety of applications and industries.

Benefits:

The "soft" core is supported by "tough" shell for improved wear resistance.

Best Used For:

Bump and splicing roll positions.

View Details -

FT-IR Spectrophotometric Analysis

FT-IR spectrophotometric analysis is one of the services we offer as part of our analytical property testing.

Benefits:

This is used to understand material composition and peformance characteristics so that the optimal material and finish recommendation can be provided for a given application.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Gold Service Contracts

We developed the Gold Service Program to improve customer service, communication, processing time, and order turn around.

Benefits:

The program is a Lean Customer Relationship process around development of a technical master specification file, and formal documentation of communication and implementation procedures.

Best Used For:

Contract Service Agreements

View Details -

Gravure Rollers

Gravure rollers are engraved or coated with a porous surface to contain ink, adhesive, or liquid until its application.

Benefits:

Liquid amounts depend on application.

Best Used For:

Gravure Rollers

View Details -

Grind Lathe Audit

We offer a grind lathe audit to investigate current equipment performance/capabilities. Three phase audit, performed on site, improves processes and can obtain increased production and better quality.

Benefits:

Finishing time can be reduced by up to 50 percent!

Best Used For:

Any lathe used in re-grinding rollers.

View Details -

Hardness Testing

Harness testing is one of the services we offer as part of our physical property testing.

Benefits:

This type of testing helps us better understand current state and correlate the data to recommendations on better performing materials for the application.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Heat Treating

Heat treating is a group of industrial and metalworking processes used to alter the physical, and sometimes chemical, properties of a material.

Benefits:

Alter physical properaties of a base metal.

Best Used For:

Often times products are specified with a heat treating requirement and the company provides this service per the specification required.

View Details -

HVOF

In this process metal particles actually travel faster than the speed of sound, generating the best bond strengths, density and hardness of all our processes.

Benefits:

HVOF does not reach temperatures that are attainable with plasma processes so materials such as ceramicsare not processed with this technique.

Best Used For:

Utilized to apply metal based coatings.

View Details -

ID Grinding

We perform Internal Diameter Grinding on complex parts.

Benefits:

Smooth internal diameter surface finish.

Best Used For:

A wide variety of applications.

View Details -

Knurled and Ground finishes

Available in a variety of aluminum and steel, our knurled and ground finishes are available for the manufacturing and repair of custom converting rollers.

Benefits:

Custom finish solutions.

Best Used For:

A wide variety of applications.

View Details -

Laminating Rollers

Our laminating rollers are available in alloy steel, carbon steel, and stainless steel.

Benefits:

part of manufacturing processes to permanently assemble objects

Best Used For:

used within the paper, film, foil, and wood industries.

View Details

Showing 31–60 of 202 results