-

Flame Treating Back Up Rollers

Flame treating back up rollers are manufactured with corrosion and heat-resistant coatings as protection from the high temperatures during flame treating.

Benefits:

Longer service life in high temperatures.

Best Used For:

Flame Treating Back Up Rollers

View Details -

Flattening Rollers

Flattening or Leveler rollers require high strength and durability as they are used in the level or “flattening” of steel or other hard metal or cement/asphalt surfaces.

Benefits:

Longer service life.

Best Used For:

Flattening Rollers

View Details -

FT-IR Spectrophotometric Analysis

FT-IR spectrophotometric analysis is one of the services we offer as part of our analytical property testing.

Benefits:

This is used to understand material composition and peformance characteristics so that the optimal material and finish recommendation can be provided for a given application.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Furnace Rollers

Furnace rollers are used to support webs and coils as they travel through ovens.

Benefits:

Products able to operate in temperatures over 600 F.

Best Used For:

Furnace Rollers

View Details -

Gold Service Contracts

We developed the Gold Service Program to improve customer service, communication, processing time, and order turn around.

Benefits:

The program is a Lean Customer Relationship process around development of a technical master specification file, and formal documentation of communication and implementation procedures.

Best Used For:

Contract Service Agreements

View Details -

Gravure Rollers

Gravure rollers are engraved or coated with a porous surface to contain ink, adhesive, or liquid until its application.

Benefits:

Liquid amounts depend on application.

Best Used For:

Gravure Rollers

View Details -

Grind Lathe Audit

We offer a grind lathe audit to investigate current equipment performance/capabilities. Three phase audit, performed on site, improves processes and can obtain increased production and better quality.

Benefits:

Finishing time can be reduced by up to 50 percent!

Best Used For:

Any lathe used in re-grinding rollers.

View Details -

Hardness Testing

Harness testing is one of the services we offer as part of our physical property testing.

Benefits:

This type of testing helps us better understand current state and correlate the data to recommendations on better performing materials for the application.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

Heat Exchanger

Heat exchangers are used in corrosive and abrasive environments.

Benefits:

Coat them with a wide range of alloys that address the issues of corrosion and abrasion.

Best Used For:

A wide range of industries and applications

View Details -

Heat Treating

Heat treating is a group of industrial and metalworking processes used to alter the physical, and sometimes chemical, properties of a material.

Benefits:

Alter physical properaties of a base metal.

Best Used For:

Often times products are specified with a heat treating requirement and the company provides this service per the specification required.

View Details -

HVOF

In this process metal particles actually travel faster than the speed of sound, generating the best bond strengths, density and hardness of all our processes.

Benefits:

HVOF does not reach temperatures that are attainable with plasma processes so materials such as ceramicsare not processed with this technique.

Best Used For:

Utilized to apply metal based coatings.

View Details -

ID Grinding

We perform Internal Diameter Grinding on complex parts.

Benefits:

Smooth internal diameter surface finish.

Best Used For:

A wide variety of applications.

View Details -

Internal Diameter Cladding

We create and apply corrosion-resistant coatings to internal diameter cladding equipment to protect their surfaces from their harsh and corrosive environments.

Benefits:

Provide corrosion protection.

Best Used For:

A wide range of applications for corrosion control.

View Details -

Knurled and Ground finishes

Available in a variety of aluminum and steel, our knurled and ground finishes are available for the manufacturing and repair of custom converting rollers.

Benefits:

Custom finish solutions.

Best Used For:

A wide variety of applications.

View Details -

Laser Cladding

Laser cladding is an additive manufacturing process that utilizes a laser to metallurgically bond performance coatings to a product’s base material.

Benefits:

The process uses the laser to create a melt pool of the base material. The coating material is introduced into this melt pool in either powder or wire form.

Best Used For:

A wide range of cladding applications; including small footprint applications.

View Details -

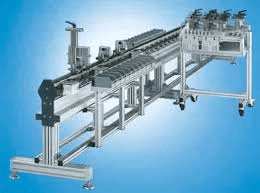

Leveler Rollers

Leveler rollers are used in metal tension leveling lines to pull metal through tension levelers.

Benefits:

Longer service life.

Best Used For:

Leveler Rollers

View Details -

LIMISTAT

Limistat is a series of electrically conductive rubber covered rollers designed to aid in dissipating static produced by webs.

Benefits:

Reduce static build-up in high speed web applications.

Best Used For:

Limistat functions best in high-speed webs that suffer from static electricity buildup.

View Details -

Liquid Dispersion

Liquid dispersion is a polymer coating process technique used in a wide variety of applications.

Benefits:

Polymer applied coatings.

Best Used For:

Wide range of polymer coating applications.

View Details -

Low Friction

Reduce the cleanup and buildup of such materials as starches, paints, adhesives, latex, rubber, food, paper, ice, sugar, resins, tapes, inks.

Benefits:

Extremely wear resistant and long lasting.

Best Used For:

Hard base onto your part and then impregnate one of our Low COF release agents into that coating.

View Details -

Machine Frame

We deisgn, engineer and apply coatings to machine frames for wear and corrosion resistance to extend their life spans.

Benefits:

Service is provided on-site.

Best Used For:

A wide range of industries and applications

View Details -

Machined Crowns

Roller crowning is intended to ensure proper web alignment and helps minimize the effects of deflection. Materials include several types of aluminum and steel.

Benefits:

Minimize the effects of deflection.

Best Used For:

A wide variety of applications.

View Details -

Mag. Particle Test

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) test for detecting surface and subsurface discontinuities in materials such as iron, nickel, cobalt, and some of their alloys.

Benefits:

Ensures product quality and uniformity.

Best Used For:

Often used as a quality verification process.

View Details -

Magna Flux Test

A magna flux test is a non-destructive testing (NDT) process for detecting surface, and subsurface, discontinuities in materials such as: iron, nickel, cobalt, and some of their alloys.

Benefits:

This process puts a magnetic field into the piece and the piece can be magnetized by direct or indirect magnetization.

Best Used For:

Often used as a quality verification process.

View Details -

-

Media Immersion Testing

Application media immersion testing is one of the services we offer as part of our Chemical Resistance Property Testing.

Benefits:

Chemical Resistance Property Testing.

Best Used For:

Wide range of problem solving applications and analysis.

View Details -

MIG Welding

Gas metal arc welding (GMAW), sometimes referred (MIG) welding or metal active gas (MAG) welding, is a welding process which heats the workpiece metal(s), causing them to melt and join.

Benefits:

A welding process in which an electric arc forms between a consumable wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to melt and join.

Best Used For:

A wide variety of welding applications.

View Details -

Mirror Finishing

Chrome plating is used where a “mirror” finish is needed.

Benefits:

Mirror finishing is a very smooth surface and can either decrease or increase web/roller friction.

Best Used For:

A wide variety of applications.

View Details

Showing 61–90 of 228 results